In the competitive and capital-intensive world of metal forging, having the right guidance at the right time can make all the difference between success and failure. Whether you’re planning to set up a new forging plant, upgrade an existing unit, or optimize production, forging consultancy services play a key role in maximizing return on investment, minimizing risks, and ensuring high-quality output.

At Forging Consultant, we offer end-to-end forging consultancy services backed by over 100 years of combined industry experience.

Our core belief is simple: “Don’t buy a machine first—call us, and we’ll give you the complete single-hand solution.”

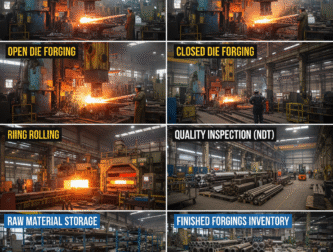

Forging consultancy involves technical, commercial, and operational guidance offered by industry experts to companies dealing in open die, closed die, cold forging, or ring rolling. The services range from:

Project feasibility studies

Machine selection & plant layout

Tooling design and die development

Process flow optimization

Production planning

Quality control systems

Civil & foundation works

Automation and IOT integration

Vendor and supplier coordination

Many investors and manufacturers jump into buying machines without fully understanding their product requirements, raw material specs, or manpower needs. Consultants ensure that you choose the right machine with the right tonnage, capacity, and automation level, saving you lakhs in rework and downtime.

Instead of dealing with 10 different vendors for machines, dies, tools, and installation, a good consultant offers a turnkey solution from concept to commissioning.

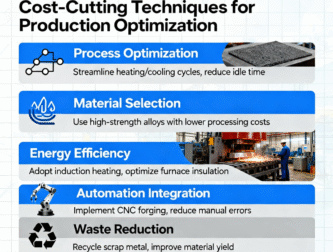

We help you optimize your plant layout, reduce cycle times, and increase first-pass yield—resulting in a quicker return on your capital investment.

From titanium and aluminum alloy forgings to automotive components and defense parts, expert consultants have worked across sectors and bring that knowledge to your specific application.

At Adhvika Forge Tech, we combine Indian ground experience with global machinery sourcing, ensuring best-in-class technology with cost-effective execution.

Our consultancy services support clients across various sectors:

🚗 Automotive Forging

✈️ Aerospace & Defense

🦾 Medical Implant Components

⚙️ General Engineering & Industrial Machinery

🔩 Bearing & Fastener Manufacturing

🔥 Oil & Gas Valves and Flanges

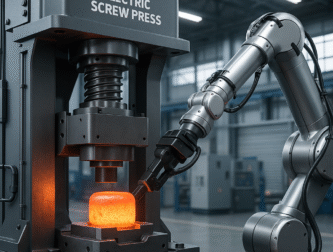

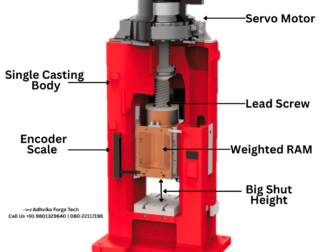

From selecting the right press (Electric Screw, Hydraulic, Drop Hammer, Mechanical) to designing the layout and civil foundation, we ensure smooth project execution.

We create robust die designs using CAD/CAM systems and optimize material flow using simulation software. Dies are designed to improve lifespan and reduce wear.

Whether it’s heating cycle control, grain flow accuracy, or flash reduction, we analyze and improve every step of your forging process.

From gear blanks and shafts to complex closed die components, we help develop new parts with clear process documentation, PPAP reports, and quality assurance.

Old presses? No problem. We repair, retrofit, and digitize existing machines with inverter drives, PLC systems, and energy-efficient components.

✅ 100+ years of team experience

✅ Pan-India and global project exposure

✅ Support for both Open Die and Closed Die Forging

✅ In-house design, simulation & automation integration

✅ End-to-end solutions: Press, Trimming, Die Handling, Automation

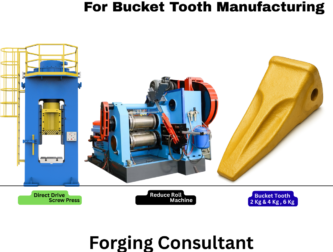

✅ Expertise in Electric Screw Press, Ring Rolling, Bucket Teeth Forging, and Medical Implants

✅ Cost-effective project execution with local Indian service teams

We have successfully delivered forging consultancy and turnkey projects for clients in:

Pune (Electric Screw Press 630T)

Jamshedpur (Crown Wheel Forging Line)

Kolhapur (Open Die Forging Project)

Middle East (Titanium Implant Forging Line)

Each project was customized, delivered on time, and is running profitably today.

Before you buy any forging machine, furnace, or die setup, talk to our experts. We will:

Guide your investment wisely

Give you an end-to-end solution

Help you scale your forging business without costly mistakes

📍 Forging Consultant

🧑💼 Contact: Amit Singh (India’s Best Forging Consultant)

📞 +91-9801329640, 080-22117198

📧 Email: info@forgingconsultant.com

🌐 Website: www.forgingconsultant.com

#AdhvikaForgeTech #ForgingConsultant #ForgingSetup #ForgingSolutions #ElectricScrewPress #ForgingLine #TurnkeyProjects #ClosedDieForging #OpenDieForging #ForgingExpertIndia

| M | T | W | T | F | S | S |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |||

| 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| 19 | 20 | 21 | 22 | 23 | 24 | 25 |

| 26 | 27 | 28 | 29 | 30 | 31 | |

Scope of Forging Consultancy Services We offer comprehensive forging c

Screw Press for Titanium and Aluminum Screw Press for Titanium and Alu

Set up your complete forging line with expert consultant Amit Singh. F

India Best Young Forging Consultant Amit Singh

Electric Screw Press: Types, Benefits, Advantages, and Services Electr

Adhvika Forge Tech offers advanced Electric Screw Presses (250–8500

🇮🇳 Aluminum Alloy Forging आज भी भारत में �

Expert Forging Consultant Amit Singh specializes in Die Design, Forgin

Blog: The Art and Science of Forging: A Key Player in Manufacturing Ex

we specialize in providing end-to-end services for the installation an

Why Electric Screw Press Offers the Cheapest Forging Cost Introduction

We handle complete services for all types of forging presses, includin

Adhvika Forge Tech manufactures Direct Drive (DD) Forging Presses powe

Adhvika Forge Tech’s Bangalore factory delivers world-class forging

Join us at IMTEX FORMING 2026 and explore how Forging Consultant can h

Claw Pole Forging Solution – Complete Turnkey Process for Automob

Get expert Forging Consultancy Services from Forging Consultant – tu

High-performance materials like titanium, alloys & composites drive ae

Aluminum forging is a manufacturing process in which aluminum alloy is

Turnkey Solutions from design to production we gives you best Turnkey

Top 10 Electric Screw Press Brand & Manufacturers Top 10 Electric Scre

Automotive Drivetrains to Connect the Driveshaft to the Transmission o

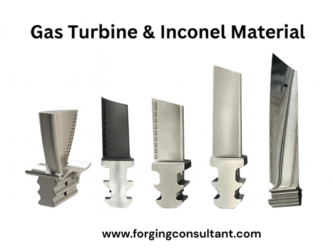

Inconel,Nimonic,Hastelloy,Nickel, Stellite Forging Solution

The cost of a 1000 Ton Electric Screw Press depends on whether you’r

Complete Hip Stem Forging Line Setup by Forging Consultant Precision F

Amit Singh is a leading forging consultant offering expertise in plant

Forging Consultant provides the best turnkey solutions for bombshell p

Cost-Cutting Techniques in Forging: Optimize Production Without Compro

Automation in forging with robots cuts cycle time by 40%, boosts outpu

Explore how 10 per kg forging rates are becoming the benchmark for ind

Open Die Forging Plant Setup – Inconel | Duplex | Super Duplex | Ste

How We Work – End-to-End Forging Solutions At Adhvika Forge Tech, le

630 Ton Electric Screw Press Price 630-ton Electric Screw Press avai

Why Choose a Forging Consultant? Are you planning to start or upgrade

Comparing Chinese and Indian screw presses in the forging industry inv

Compare forged vs cast bucket teeth: durability, wear resistance, cost

Aluminum Crown Forging Experts – Precision, Efficiency & Durabil

Complete Turnkey Solution for Bucket Tooth Manufacturing

Adhvika Forge Tech provides skilled forging manpower supply, covering

1️⃣ Material Selection Matters 🏗️ – Choosing the right allo

Aluminum and aluminum alloy forging involves shaping these materials t

Direct Drive Electric Screw Press – Energy saving, high precision &

At Forging Consultant, we provide turnkey solutions for closed die for

High-Strength Railway Forging Components – End-to-End Solutions for

Why Forging Consultant Services Are Essential for Your Business Runnin

The forging industry is evolving rapidly, with advancements in technol

In the dynamic and demanding world of forging, where precision, effici

Amit Singh – A Global Forging Consultant Changing the Future of Forg

India Best Supplier Hot Forging Press Top 10 AD Electric Screw Press &

Discover Amit Singh’s expertise in forging consultancy and turnk

The railway forging industry is evolving fast 🚆 — blending human

Forging Consultancy Group is proud to participate in Metal Forming Exp

A Ring Rolling Machine is used to manufacture hollow, ring-shaped comp

Shaping the Future of Forging with Vision, Experience & Innovation

Error: Contact form not found.