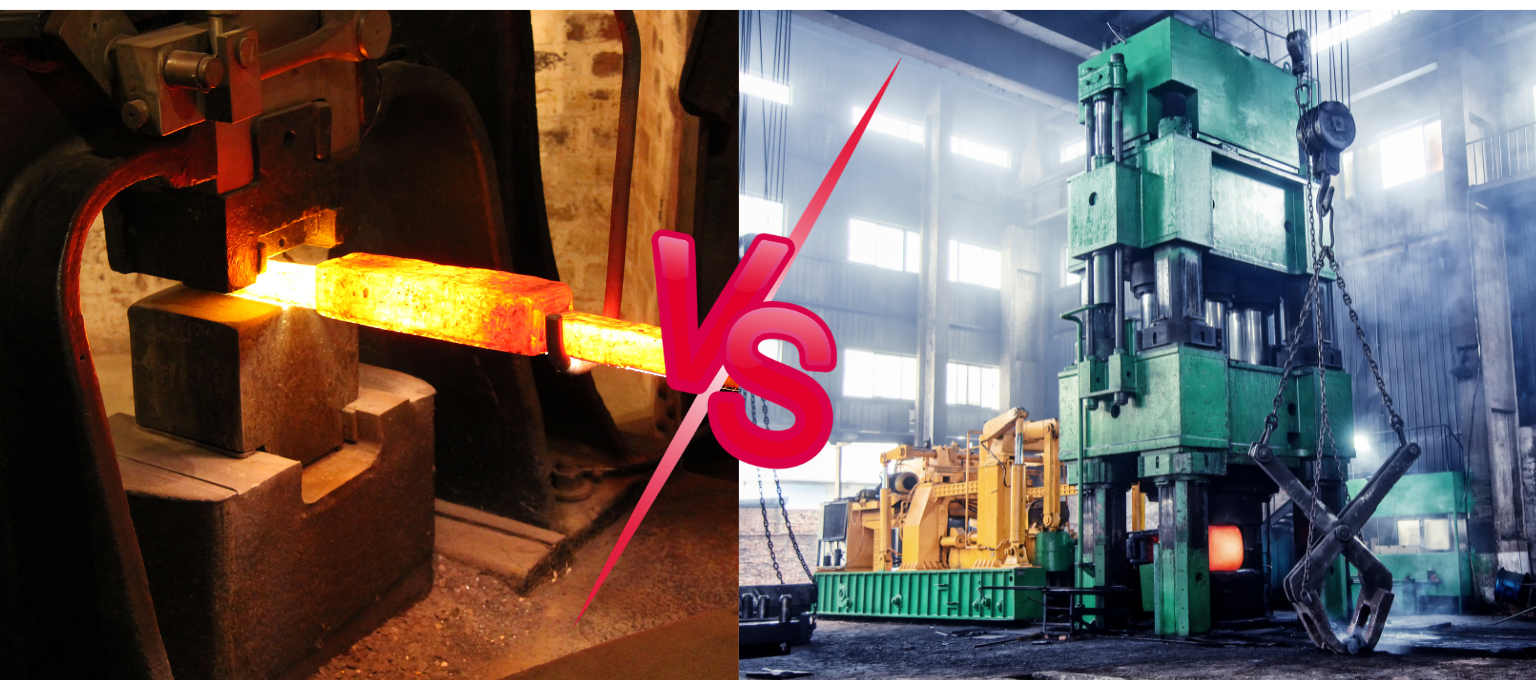

Comparing Chinese and Indian screw presses in the forging industry involves examining several critical aspects such as technology, reliability, cost-effectiveness, and service support. Here’s a detailed comparison to help you understand the differences and considerations between these two options.

Indian manufacturers of screw presses have also made significant strides in technology adoption, focusing on precision engineering and customization to meet specific industry needs. Companies like Adhvika Forge Tech leverage local expertise combined with global technology partnerships to offer robust solutions tailored to Indian and international standards. Indian screw presses are noted for their reliability and suitability for diverse forging applications, particularly in sectors like automotive, aerospace, and defense.

Chinese screw presses are known for their high production rates and operational efficiency. They often integrate advanced automation features, such as PLC control systems and digital interfaces, enhancing precision and repeatability in forging processes. These presses are designed to handle a wide range of materials and forging techniques, supporting both traditional and advanced forging methods.

Indian screw presses prioritize energy efficiency and operational reliability. They are engineered to deliver consistent performance under varying operational conditions, ensuring minimal downtime and maximum productivity. Indian manufacturers often emphasize customization and flexibility, allowing for tailored solutions that meet specific client requirements and production demands.

Quality standards in Chinese screw presses have improved significantly over the years, with many manufacturers adhering to international quality certifications and standards. However, there can be variability in quality depending on the manufacturer and the level of oversight in production processes. Customers often look for reputed brands that offer robust warranties and after-sales support to mitigate risks associated with product durability.

Indian screw presses are recognized for their sturdy construction and durability. Manufacturers like Adhvika Forge Tech focus on stringent quality control measures throughout the manufacturing process, ensuring adherence to industry standards and customer specifications. They offer comprehensive service packages and extended warranties, reinforcing the reliability and longevity of their products in demanding forging environments.

Chinese screw presses are generally perceived as cost-effective solutions, appealing to businesses looking to optimize initial capital expenditures. The competitive pricing of these presses, coupled with their technological advancements, makes them attractive for entry-level to mid-range forging operations seeking economical yet efficient solutions.

Indian screw presses often provide value-driven propositions, balancing initial investment costs with long-term operational benefits. While initial purchase prices may vary depending on specifications and customization, Indian manufacturers emphasize total cost of ownership (TCO) advantages, including lower maintenance costs and higher uptime, contributing to overall cost-effectiveness over the equipment’s lifecycle.

Chinese manufacturers have expanded their global footprint, offering robust after-sales service networks in key markets. They provide technical support, spare parts availability, and training programs to enhance customer satisfaction and operational efficiency. However, logistical challenges and language barriers may occasionally impact service delivery timelines.

Indian screw press manufacturers like Adhvika Forge Tech prioritize customer-centric service models, offering localized support and responsive service teams. They provide comprehensive maintenance contracts, prompt spare parts availability, and training sessions tailored to client needs. This localized approach enhances customer trust and ensures minimal downtime in critical forging operations.

Chinese screw presses have gained significant market share globally, driven by competitive pricing strategies and technological advancements. They cater to diverse industrial segments, positioning China as a key player in the global forging machinery market. However, market perception regarding quality consistency and intellectual property rights (IPR) protection remains a consideration for international buyers.

Indian screw presses are increasingly recognized for their innovation, reliability, and customer-centric approach. Companies like Adhvika Forge Tech are expanding their global presence by offering tailored solutions and fostering long-term partnerships with international clients. They leverage India’s manufacturing prowess and engineering capabilities to deliver high-quality forging machinery solutions with a strong emphasis on customer satisfaction and operational excellence.

| M | T | W | T | F | S | S |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |||

| 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| 19 | 20 | 21 | 22 | 23 | 24 | 25 |

| 26 | 27 | 28 | 29 | 30 | 31 | |

Scope of Forging Consultancy Services We offer comprehensive forging c

Screw Press for Titanium and Aluminum Screw Press for Titanium and Alu

Set up your complete forging line with expert consultant Amit Singh. F

India Best Young Forging Consultant Amit Singh

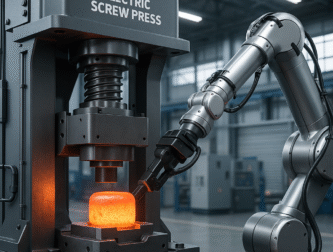

Electric Screw Press: Types, Benefits, Advantages, and Services Electr

Adhvika Forge Tech offers advanced Electric Screw Presses (250–8500

🇮🇳 Aluminum Alloy Forging आज भी भारत में �

Expert Forging Consultant Amit Singh specializes in Die Design, Forgin

Blog: The Art and Science of Forging: A Key Player in Manufacturing Ex

we specialize in providing end-to-end services for the installation an

Why Electric Screw Press Offers the Cheapest Forging Cost Introduction

We handle complete services for all types of forging presses, includin

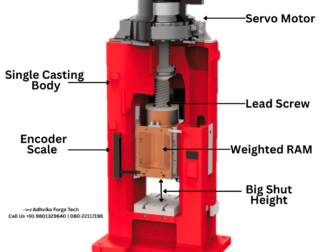

Adhvika Forge Tech manufactures Direct Drive (DD) Forging Presses powe

Adhvika Forge Tech’s Bangalore factory delivers world-class forging

Join us at IMTEX FORMING 2026 and explore how Forging Consultant can h

Claw Pole Forging Solution – Complete Turnkey Process for Automob

Get expert Forging Consultancy Services from Forging Consultant – tu

High-performance materials like titanium, alloys & composites drive ae

Aluminum forging is a manufacturing process in which aluminum alloy is

Turnkey Solutions from design to production we gives you best Turnkey

Top 10 Electric Screw Press Brand & Manufacturers Top 10 Electric Scre

Automotive Drivetrains to Connect the Driveshaft to the Transmission o

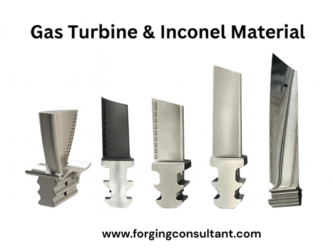

Inconel,Nimonic,Hastelloy,Nickel, Stellite Forging Solution

The cost of a 1000 Ton Electric Screw Press depends on whether you’r

Complete Hip Stem Forging Line Setup by Forging Consultant Precision F

Amit Singh is a leading forging consultant offering expertise in plant

Forging Consultant provides the best turnkey solutions for bombshell p

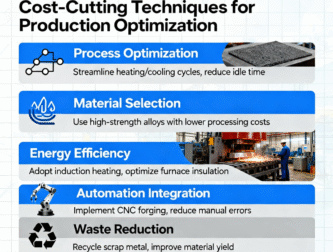

Cost-Cutting Techniques in Forging: Optimize Production Without Compro

Automation in forging with robots cuts cycle time by 40%, boosts outpu

Explore how 10 per kg forging rates are becoming the benchmark for ind

Open Die Forging Plant Setup – Inconel | Duplex | Super Duplex | Ste

How We Work – End-to-End Forging Solutions At Adhvika Forge Tech, le

630 Ton Electric Screw Press Price 630-ton Electric Screw Press avai

Why Choose a Forging Consultant? Are you planning to start or upgrade

Comparing Chinese and Indian screw presses in the forging industry inv

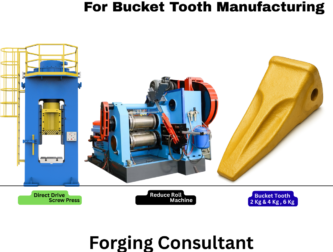

Compare forged vs cast bucket teeth: durability, wear resistance, cost

Aluminum Crown Forging Experts – Precision, Efficiency & Durabil

Complete Turnkey Solution for Bucket Tooth Manufacturing

Adhvika Forge Tech provides skilled forging manpower supply, covering

1️⃣ Material Selection Matters 🏗️ – Choosing the right allo

Aluminum and aluminum alloy forging involves shaping these materials t

Direct Drive Electric Screw Press – Energy saving, high precision &

At Forging Consultant, we provide turnkey solutions for closed die for

High-Strength Railway Forging Components – End-to-End Solutions for

Why Forging Consultant Services Are Essential for Your Business Runnin

The forging industry is evolving rapidly, with advancements in technol

In the dynamic and demanding world of forging, where precision, effici

Amit Singh – A Global Forging Consultant Changing the Future of Forg

India Best Supplier Hot Forging Press Top 10 AD Electric Screw Press &

Discover Amit Singh’s expertise in forging consultancy and turnk

The railway forging industry is evolving fast 🚆 — blending human

Forging Consultancy Group is proud to participate in Metal Forming Exp

A Ring Rolling Machine is used to manufacture hollow, ring-shaped comp

Shaping the Future of Forging with Vision, Experience & Innovation

Error: Contact form not found.