Electric Screw Press – Precision forging press offering high accuracy, energy savings, low maintenance, and reliable performance for industrial applications.

Electric Screw Press

Introduction to Electric Screw Press

Electric Screw Press is a modern forging solution designed to deliver high-precision and efficient metal forming. It combines advanced screw technology with electric drive systems to provide consistent force, accuracy, and repeatability in forging operations. Ideal for automotive, aerospace, defense, and industrial components, it ensures optimal material utilization and reduces energy consumption compared to traditional mechanical or hydraulic presses. With minimal maintenance requirements and user-friendly controls, the press enhances productivity and prolongs die life. Its versatile design supports a wide range of forging processes including sizing, calibration, leveling, and light upsetting. The Electric Screw Press offers unmatched reliability, energy efficiency, and precise control, making it a preferred choice for manufacturers seeking high-quality, cost-effective forging solutions..

Working Principle & Structure

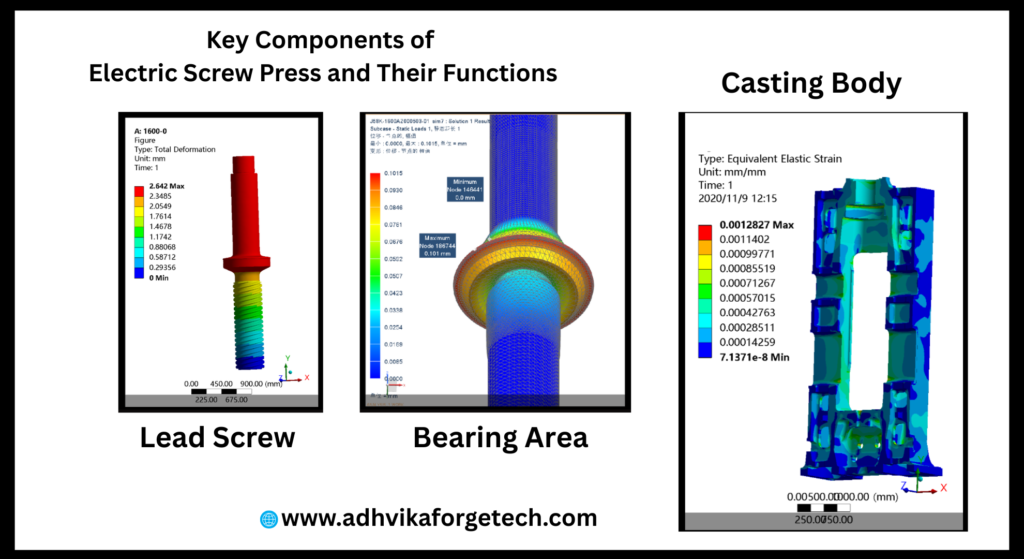

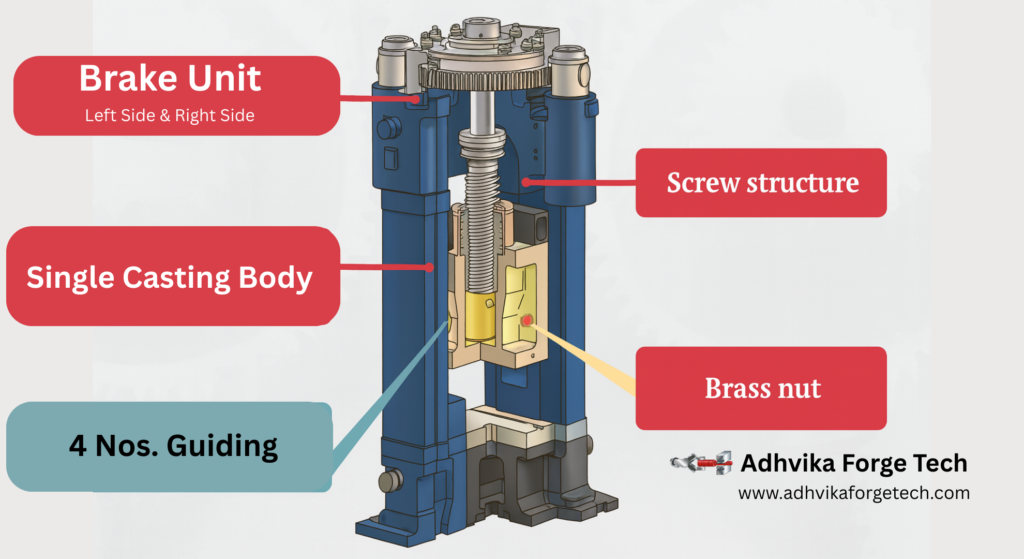

Electric Screw Press operates on the principle of converting rotational motion into linear motion using a precision-engineered screw and nut mechanism. The electric motor drives the screw, which moves the ram vertically to apply controlled force on the workpiece. Unlike traditional mechanical presses, the screw mechanism ensures uniform pressure, high accuracy, and repeatable performance throughout the forging cycle. The nut, usually made of bronze or high-strength material, provides excellent wear resistance and smooth sliding under heavy loads. The guiding system, combined with adjustable guide plates, maintains precise alignment of the ram, preventing deviation and ensuring consistent product quality. Energy-efficient motors and inverter drives allow precise control of speed, force, and stroke, while reducing power consumption. The press is suitable for a variety of forging processes, including sizing, calibration, leveling, and light upsetting, making it ideal for automotive, aerospace, and industrial applications. Its design ensures durability, low maintenance, and optimal die life.

Technical Parameters of Electric Screw Press

Nominal force |

KN |

1600 |

2500 |

3150 |

4000 |

6300 |

10000 |

16000 |

25000 |

40000 |

Max. working force |

KN |

2500 |

4000 |

5000 |

6300 |

10000 |

16000 |

25000 |

40000 |

63000 |

Max. forging energy |

KJ |

10 |

15 |

20 |

40 |

80 |

160 |

280 |

500 |

1000 |

Slide stroke |

mm |

300 |

320 |

380 |

400 |

450 |

580 |

600 |

630 |

750 |

Theoretical strokes |

min⁻¹ |

30 |

28 |

26 |

20 |

19 |

18 |

15 |

14 |

10 |

Min. enclose height |

mm |

500 |

520 |

550 |

570 |

720 |

870 |

960 |

1050 |

1460 |

Thickness of sow block |

mm |

120 |

120 |

120 |

120 |

160 |

180 |

220 |

250 |

300 |

Enclose height range of die |

mm |

380 ~ |

380 ~ |

430 ~ |

450 ~ |

560 ~ |

570 ~ |

740 ~ |

800 ~ |

1160 ~ |

Size of worktable (width x depth) |

mm |

600×560 |

600×560 |

700×640 |

750×730 |

820×900 |

920×1050 |

1000×1280 |

1200×1400 |

1600×1900 |

Types of Electric Screw Press

-

Direct Drive Electric Screw Press

-

The motor is directly coupled to the screw, eliminating gears.

-

Offers high efficiency, precise force control, and lower maintenance.

-

Ideal for precision forging of automotive, aerospace, and titanium components.

-

-

Gear Drive Electric Screw Press

-

Uses a gear system between motor and screw to amplify torque.

-

Provides higher force for heavy-duty forging applications.

-

Suitable for steel components, flanges, shafts, and large automotive parts.

-

-

Servo-Controlled Electric Screw Press

-

Integrated with a servo motor and PLC for precise speed, position, and force control.

-

Allows programmable forging cycles, multi-stage forging, and complex shapes.

-

Excellent for aerospace, defense, and specialized industrial components.

-

-

High-Speed Electric Screw Press

-

Designed for high-production environments.

-

Provides rapid forging cycles without compromising accuracy.

-

Commonly used in mass automotive and industrial part production.

-

-

Multi-Stage Electric Screw Press

-

Capable of performing multiple forging operations in one cycle.

-

Reduces handling, increases efficiency, and improves die life.

-

Used for complex shapes or high-volume production lines.

-

Electric Screw Press – Robust Structure Ensuring Precision, Durability, and High-Performance Forging

We help you set up your Electric Screw Press with complete turnkey support

Assessment & Selection: Evaluate production needs and choose the suitable Electric Screw Press.

-

Foundation Design: Prepare civil foundation and reinforcement layout as per press specifications.

-

Shipping & Installation: Transport, position, and align the press accurately.

-

Commissioning: Connect electrical, mechanical, and automation systems.

-

Trial & Optimization: Run trial forgings and fine-tune parameters for best performance.

-

Training & Support: Train your team and provide ongoing technical support for smooth operation.