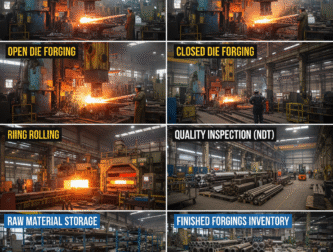

A Ring Rolling Machine is used to manufacture hollow, ring-shaped components from solid billets. The machine applies high levels of pressure and heat to stretch and shape the billet into a ring. These rings are essential in various sectors, including the production of turbine rings, gear rings, flanges, and bushings.

In the world of forging, the production of rings—whether for aerospace, automotive, or energy industries—requires high precision and advanced technology. Ring Rolling Machines have become indispensable for manufacturers seeking to produce high-quality, accurate, and cost-effective rings. At Adhvika Forge Tech, we specialize in providing state-of-the-art Ring Rolling Machines that meet the demands of various industries, ensuring superior quality and high productivity.

A Ring Rolling Machine is used to manufacture hollow, ring-shaped components from solid billets. The machine applies high levels of pressure and heat to stretch and shape the billet into a ring. These rings are essential in various sectors, including the production of turbine rings, gear rings, flanges, and bushings.

One of the most significant advantages of Ring Rolling Machines is their ability to produce extremely accurate and precise rings. The CNC-controlled machines offer highly uniform wall thickness, perfect roundness, and tight tolerances. This level of precision is essential for industries such as aerospace, where even the smallest deviation can result in major performance issues.

With the ability to process large volumes quickly, Ring Rolling Machines offer high productivity. The automation and computer-controlled features allow for fast setup, repeatable processes, and consistent quality, reducing overall cycle time and increasing throughput. For high-demand industries like automotive and energy, where time is critical, these machines deliver efficient results without compromising on quality.

Ring Rolling Machines are versatile and can handle various materials, including alloy steels, titanium, nickel alloys, and aluminum. This flexibility allows manufacturers to cater to a wide array of industries, from producing lightweight rings for automotive applications to high-strength rings for power generation.

Modern Ring Rolling Machines are designed with energy efficiency in mind. By utilizing advanced servo-drive systems and optimized control processes, these machines minimize energy consumption while maximizing output. This makes them an excellent choice for companies looking to reduce their environmental impact and lower operational costs.

Ring Rolling Machines are highly adaptable. They can produce rings of varying diameters, thicknesses, and weights depending on the specific requirements of the project. Whether you need small-diameter rings for automotive gears or large-diameter rings for turbine components, the machine can be adjusted to meet the exact specifications needed.

The precision of Ring Rolling Machines results in minimal material waste compared to other forging processes. The machine optimizes material utilization by applying just the right amount of force and heat, ensuring that the final product is close to its desired dimensions with minimal need for additional machining.

Unlike other forging methods, Ring Rolling Machines provide a smooth surface finish without the need for additional finishing processes. This reduces post-forging processing time and cost, making the process even more efficient and economical.

Ring Rolling Machines are built to handle high-force applications and are designed for long-term durability. With robust frames and precise engineering, these machines can withstand heavy workloads, making them suitable for high-volume production in industries that demand reliability and performance.

The machine’s design and control systems allow for the creation of rings with complex geometries, including tapered rings, rings with varying cross-sections, and thin-walled rings. This flexibility is crucial for industries requiring components with specialized shapes or custom designs.

Ring Rolling Machines are used across a wide range of industries, including:

Aerospace: Manufacturing high-strength rings for turbine engines, rotor shafts, and other critical components.

Automotive: Producing gear rings, hubs, and flanges for engines, transmissions, and other assemblies.

Energy: Forging rings for turbines, pumps, and valves in power plants.

Defense: Manufacturing specialized rings used in military equipment and systems.

At Adhvika Forge Tech, we specialize in providing high-performance Ring Rolling Machines designed to meet the specific needs of our clients. Our machines offer the perfect blend of advanced technology, energy efficiency, and precision, ensuring you get the best results for your forging requirements.

We understand that every client’s needs are unique. Our Ring Rolling Machines can be tailored to meet your specific production requirements, whether you need custom-sized rings, specialized materials, or enhanced automation features.

We don’t just provide Ring Rolling Machines—we offer complete turnkey solutions. From machine selection to installation, commissioning, and after-sales support, our team is with you every step of the way to ensure seamless operations.

With clients across the globe, Adhvika Forge Tech has earned a reputation for delivering reliable and high-quality forging solutions. Whether you’re located in India, Europe, North America, or Asia, we have the capability to serve your forging needs with precision and efficiency.

Our commitment to customer satisfaction doesn’t end with installation. We provide comprehensive maintenance services, ensuring that your Ring Rolling Machine continues to perform optimally throughout its lifecycle. Our support team is always ready to assist with troubleshooting, upgrades, and spare parts.

Ring Rolling Machines have become an indispensable part of the forging industry, offering unmatched precision, flexibility, and efficiency. With Adhvika Forge Tech at your side, you can be confident in receiving state-of-the-art solutions that will help take your manufacturing operations to the next level. Whether you’re producing automotive components, aerospace parts, or energy-sector rings, our Ring Rolling Machines will provide you with the reliability and performance you need.

Get in touch with Adhvika Forge Tech today to explore how our Ring Rolling Machines can help transform your forging operations, improve product quality, and reduce production costs.

| M | T | W | T | F | S | S |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |||

| 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| 19 | 20 | 21 | 22 | 23 | 24 | 25 |

| 26 | 27 | 28 | 29 | 30 | 31 | |

Scope of Forging Consultancy Services We offer comprehensive forging c

Screw Press for Titanium and Aluminum Screw Press for Titanium and Alu

Set up your complete forging line with expert consultant Amit Singh. F

India Best Young Forging Consultant Amit Singh

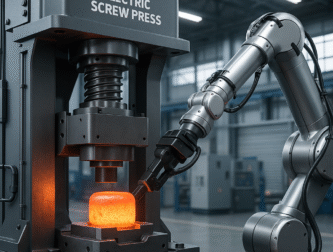

Electric Screw Press: Types, Benefits, Advantages, and Services Electr

Adhvika Forge Tech offers advanced Electric Screw Presses (250–8500

🇮🇳 Aluminum Alloy Forging आज भी भारत में �

Expert Forging Consultant Amit Singh specializes in Die Design, Forgin

Blog: The Art and Science of Forging: A Key Player in Manufacturing Ex

we specialize in providing end-to-end services for the installation an

Why Electric Screw Press Offers the Cheapest Forging Cost Introduction

We handle complete services for all types of forging presses, includin

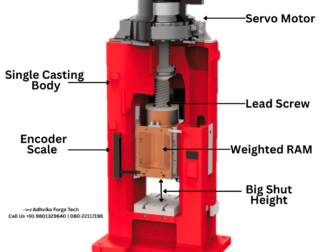

Adhvika Forge Tech manufactures Direct Drive (DD) Forging Presses powe

Adhvika Forge Tech’s Bangalore factory delivers world-class forging

Join us at IMTEX FORMING 2026 and explore how Forging Consultant can h

Claw Pole Forging Solution – Complete Turnkey Process for Automob

Get expert Forging Consultancy Services from Forging Consultant – tu

High-performance materials like titanium, alloys & composites drive ae

Aluminum forging is a manufacturing process in which aluminum alloy is

Turnkey Solutions from design to production we gives you best Turnkey

Top 10 Electric Screw Press Brand & Manufacturers Top 10 Electric Scre

Automotive Drivetrains to Connect the Driveshaft to the Transmission o

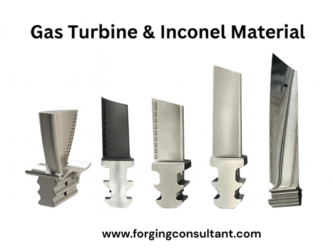

Inconel,Nimonic,Hastelloy,Nickel, Stellite Forging Solution

The cost of a 1000 Ton Electric Screw Press depends on whether you’r

Complete Hip Stem Forging Line Setup by Forging Consultant Precision F

Amit Singh is a leading forging consultant offering expertise in plant

Forging Consultant provides the best turnkey solutions for bombshell p

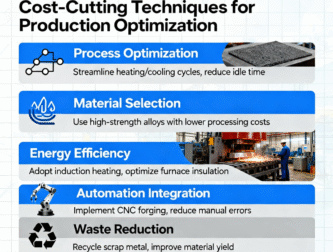

Cost-Cutting Techniques in Forging: Optimize Production Without Compro

Automation in forging with robots cuts cycle time by 40%, boosts outpu

Explore how 10 per kg forging rates are becoming the benchmark for ind

Open Die Forging Plant Setup – Inconel | Duplex | Super Duplex | Ste

How We Work – End-to-End Forging Solutions At Adhvika Forge Tech, le

630 Ton Electric Screw Press Price 630-ton Electric Screw Press avai

Why Choose a Forging Consultant? Are you planning to start or upgrade

Comparing Chinese and Indian screw presses in the forging industry inv

Compare forged vs cast bucket teeth: durability, wear resistance, cost

Aluminum Crown Forging Experts – Precision, Efficiency & Durabil

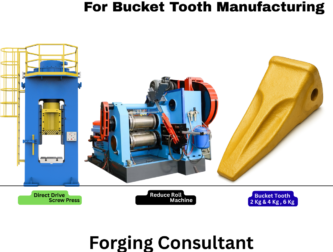

Complete Turnkey Solution for Bucket Tooth Manufacturing

Adhvika Forge Tech provides skilled forging manpower supply, covering

1️⃣ Material Selection Matters 🏗️ – Choosing the right allo

Aluminum and aluminum alloy forging involves shaping these materials t

Direct Drive Electric Screw Press – Energy saving, high precision &

At Forging Consultant, we provide turnkey solutions for closed die for

High-Strength Railway Forging Components – End-to-End Solutions for

Why Forging Consultant Services Are Essential for Your Business Runnin

The forging industry is evolving rapidly, with advancements in technol

In the dynamic and demanding world of forging, where precision, effici

Amit Singh – A Global Forging Consultant Changing the Future of Forg

India Best Supplier Hot Forging Press Top 10 AD Electric Screw Press &

Discover Amit Singh’s expertise in forging consultancy and turnk

The railway forging industry is evolving fast 🚆 — blending human

Forging Consultancy Group is proud to participate in Metal Forming Exp

A Ring Rolling Machine is used to manufacture hollow, ring-shaped comp

Shaping the Future of Forging with Vision, Experience & Innovation

Error: Contact form not found.