Automotive Drivetrains to Connect the Driveshaft to the Transmission or Differential, allowing for the transmission of torque while accommodating angle changes.

The part in the image is a universal joint yoke or U-joint yoke. It is commonly used in automotive drivetrains to connect the driveshaft to the transmission or differential, allowing for the transmission of torque while accommodating angle changes.

The universal joint yoke (U-joint yoke) is typically made from high-strength steel alloys, including grades like:

Forged Carbon Steel (e.g., AISI 4140) – Common for U-joint yokes in automotive applications due to its good balance of strength, toughness, and wear resistance.

Alloy Steel (e.g., AISI 4340 or 8620) – Often used for more demanding applications requiring higher strength and fatigue resistance.

Stainless Steel (e.g., AISI 304 or 316) – Occasionally used in environments where corrosion resistance is critical (marine or chemical industries).

The specific grade depends on the application requirements, such as strength, toughness, and resistance to wear or corrosion.

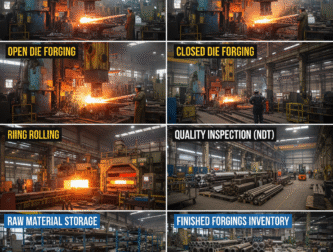

How a Forging Consultant Can Help Set Up a Forging Plant

Setting up a forging plant involves multiple stages, from planning and designing to equipment procurement and operational optimization. A forging consultant plays a crucial role in ensuring that the plant is set up efficiently and effectively. Here’s how a forging consultant can help you establish a state-of-the-art forging facility:

A forging consultant begins by evaluating the feasibility of the project, considering factors like:

Market demand for the forged components.

Material availability.

Location benefits (logistics, labor, etc.).

Financial projections (ROI, cost estimates, break-even point).

The consultant creates a comprehensive business plan, including capital investments, projected revenues, and operational costs. This helps you understand the financial aspects before diving into plant setup.

The choice of location is critical for forging plants. A forging consultant assists in identifying optimal sites based on:

Proximity to raw materials, customers, and suppliers.

Access to skilled labor.

Utilities and infrastructure (water, electricity, waste disposal).

Once the site is selected, the consultant designs an efficient plant layout that maximizes production flow, reduces bottlenecks, and ensures compliance with safety standards.

A key task of the forging consultant is to select the right machines and equipment for the plant. This includes:

Forging presses (e.g., hydraulic, mechanical, or direct drive screw presses).

Furnaces (induction, gas-fired, or electric).

Automation systems for robotic handling, material transport, and process monitoring.

The consultant ensures the equipment meets the desired production capacity, quality standards, and energy efficiency goals.

Once the equipment is chosen, the consultant helps in designing the forging process, which includes:

Tooling design (dies, molds, and fixtures).

Process parameters (temperature, pressure, cycle times).

Material selection and heat treatment methods.

They ensure that the forging processes are optimized for maximum efficiency, quality, and minimal waste, which translates into better cost savings and higher yield.

A forging plant must adhere to local and international safety standards and environmental regulations. The consultant ensures that:

The plant complies with OSHA (Occupational Safety and Health Administration) standards and other safety protocols.

Environmental sustainability is considered, minimizing waste, emissions, and energy consumption.

They will help you integrate ISO certifications (like ISO 9001 for quality management) to maintain the highest standards in your operations.

A forging consultant often takes on the role of project manager during the plant setup. They:

Coordinate with contractors, suppliers, and installation teams.

Ensure that construction, equipment installation, and commissioning are done on time and within budget.

Handle quality control during setup to ensure the plant operates as designed.

This ensures the plant’s operations commence smoothly and without unnecessary delays.

A forging plant needs skilled operators and technicians to manage equipment, control processes, and maintain machinery. The consultant:

Provides training programs for plant personnel on operating machinery, handling materials, and maintaining safety.

Implements continuous improvement processes to help the workforce stay updated on new technologies and methods.

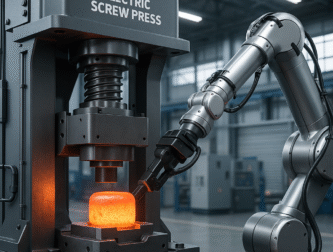

Automation is essential for increasing production rates, minimizing errors, and enhancing quality. A forging consultant helps in:

Integrating control systems for monitoring forging parameters (temperature, pressure, time).

Implementing robotic automation for material handling, billet loading/unloading, and part inspection.

This reduces human errors, speeds up the production process, and improves overall efficiency.

Once the forging plant is operational, a consultant continues to offer after-sales support, including:

Maintenance scheduling to ensure the longevity of machines.

Regular process audits to identify areas for optimization.

Assistance with troubleshooting to resolve issues that arise during production.

The consultant’s role doesn’t end with the plant’s commissioning. Continuous support ensures the plant operates at peak efficiency throughout its lifecycle.

Efficient supply chain management is essential for a forging plant’s success. A forging consultant helps:

Design the material flow system, ensuring smooth movement of raw materials, semi-finished products, and finished goods.

Develop relationships with raw material suppliers and logistics providers to ensure a steady supply of inputs and timely delivery of forged products.

The consultant ensures that you have an efficient system for managing your inventory, reducing downtime, and maintaining high production levels.

A forging consultant also helps track the financial performance of the plant:

They monitor ongoing costs, identify opportunities for cost reduction, and assess the profitability of the plant.

By performing cost-benefit analysis, they ensure that the plant delivers a solid return on investment (ROI).

This helps ensure long-term sustainability and profitability in the competitive forging market.

A forging consultant plays an indispensable role in setting up a successful forging plant. They offer expert guidance throughout the entire process—from feasibility analysis and site selection to equipment procurement, process optimization, and staff training. Their expertise ensures that the plant runs efficiently, complies with regulations, and maximizes profitability. By leveraging their knowledge, you can avoid common pitfalls, optimize operations, and meet the high standards required in industries like automotive, aerospace, defense, and railways.

| M | T | W | T | F | S | S |

|---|---|---|---|---|---|---|

| 1 | ||||||

| 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| 16 | 17 | 18 | 19 | 20 | 21 | 22 |

| 23 | 24 | 25 | 26 | 27 | 28 | |

Scope of Forging Consultancy Services We offer comprehensive forging c

Screw Press for Titanium and Aluminum Screw Press for Titanium and Alu

Forging is more than shaping heated metal — it is a process that dem

Set up your complete forging line with expert consultant Amit Singh. F

India Best Young Forging Consultant Amit Singh

Electric Screw Press: Types, Benefits, Advantages, and Services Electr

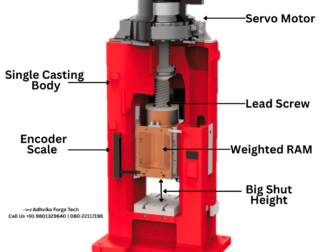

Adhvika Forge Tech offers advanced Electric Screw Presses (250–8500

🇮🇳 Aluminum Alloy Forging आज भी भारत में �

Expert Forging Consultant Amit Singh specializes in Die Design, Forgin

Blog: The Art and Science of Forging: A Key Player in Manufacturing Ex

we specialize in providing end-to-end services for the installation an

Why Electric Screw Press Offers the Cheapest Forging Cost Introduction

We handle complete services for all types of forging presses, includin

Adhvika Forge Tech manufactures Direct Drive (DD) Forging Presses powe

Adhvika Forge Tech’s Bangalore factory delivers world-class forging

Join us at IMTEX FORMING 2026 and explore how Forging Consultant can h

Claw Pole Forging Solution – Complete Turnkey Process for Automob

Get expert Forging Consultancy Services from Forging Consultant – tu

High-performance materials like titanium, alloys & composites drive ae

Aluminum forging is a manufacturing process in which aluminum alloy is

Turnkey Solutions from design to production we gives you best Turnkey

Top 10 Electric Screw Press Brand & Manufacturers Top 10 Electric Scre

Automotive Drivetrains to Connect the Driveshaft to the Transmission o

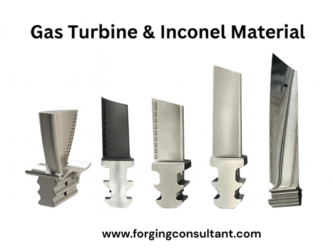

Inconel,Nimonic,Hastelloy,Nickel, Stellite Forging Solution

The cost of a 1000 Ton Electric Screw Press depends on whether you’r

Complete Hip Stem Forging Line Setup by Forging Consultant Precision F

Amit Singh is a leading forging consultant offering expertise in plant

Forging Consultant provides the best turnkey solutions for bombshell p

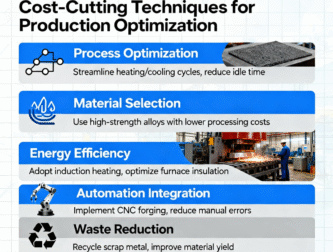

Cost-Cutting Techniques in Forging: Optimize Production Without Compro

Automation in forging with robots cuts cycle time by 40%, boosts outpu

Explore how 10 per kg forging rates are becoming the benchmark for ind

Open Die Forging Plant Setup – Inconel | Duplex | Super Duplex | Ste

How We Work – End-to-End Forging Solutions At Adhvika Forge Tech, le

630 Ton Electric Screw Press Price 630-ton Electric Screw Press avai

Why Choose a Forging Consultant? Are you planning to start or upgrade

Comparing Chinese and Indian screw presses in the forging industry inv

Compare forged vs cast bucket teeth: durability, wear resistance, cost

Aluminum Crown Forging Experts – Precision, Efficiency & Durabil

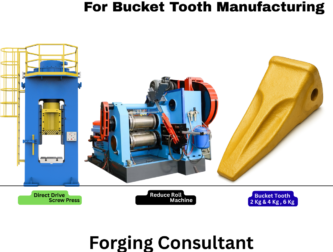

Complete Turnkey Solution for Bucket Tooth Manufacturing

Adhvika Forge Tech provides skilled forging manpower supply, covering

1️⃣ Material Selection Matters 🏗️ – Choosing the right allo

Aluminum and aluminum alloy forging involves shaping these materials t

Direct Drive Electric Screw Press – Energy saving, high precision &

At Forging Consultant, we provide turnkey solutions for closed die for

High-Strength Railway Forging Components – End-to-End Solutions for

Why Forging Consultant Services Are Essential for Your Business Runnin

The forging industry is evolving rapidly, with advancements in technol

In the dynamic and demanding world of forging, where precision, effici

Amit Singh – A Global Forging Consultant Changing the Future of Forg

India Best Supplier Hot Forging Press Top 10 AD Electric Screw Press &

Discover Amit Singh’s expertise in forging consultancy and turnk

The railway forging industry is evolving fast 🚆 — blending human

Forging Consultancy Group is proud to participate in Metal Forming Exp

A Ring Rolling Machine is used to manufacture hollow, ring-shaped comp

Shaping the Future of Forging with Vision, Experience & Innovation

Error: Contact form not found.