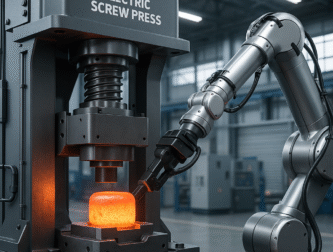

Automation in forging with robots cuts cycle time by 40%, boosts output & safety, and saves energy. We Gives You Best – turnkey forging solutions.

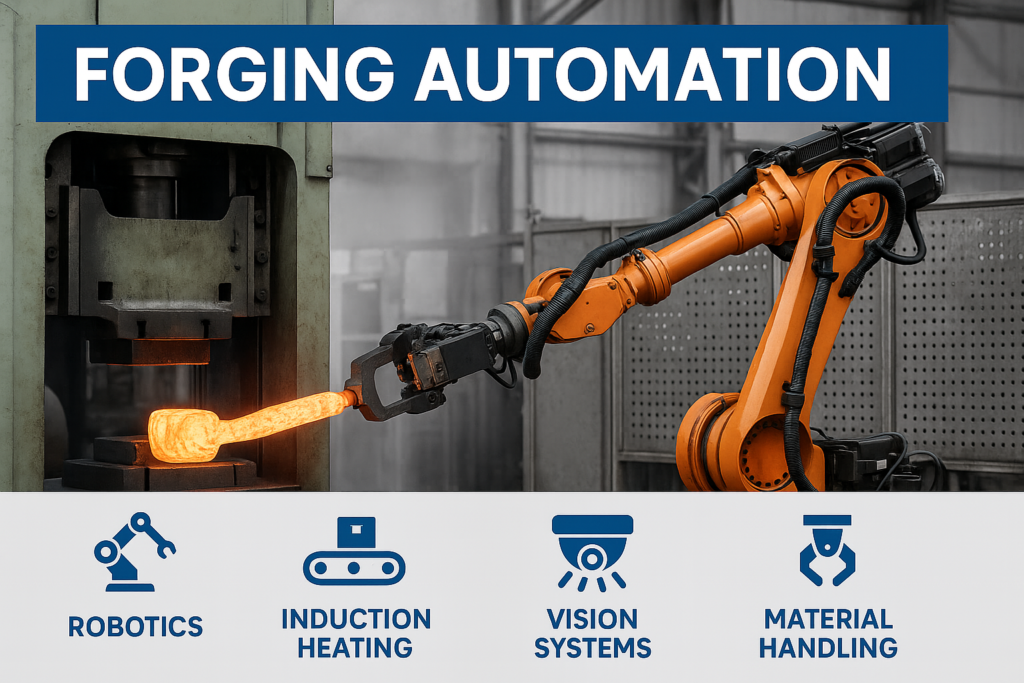

In the forging industry, time is money – every second saved in production directly impacts profitability. At Adhvika Forge Tech, we believe automation is not just the future of forging… it’s the present. Robotic automation in forging is transforming how we handle hot billets, move dies, and execute precise forging operations with speed, safety, and accuracy.

In a conventional forging line, the billet transfer, die loading, and finished part removal are often done manually or semi-manually. This leads to:

Longer cycle times due to manual handling delays

Inconsistent billet positioning, affecting product quality

Higher labor fatigue and risk of workplace accidents

Difficulty maintaining temperature consistency during transfers

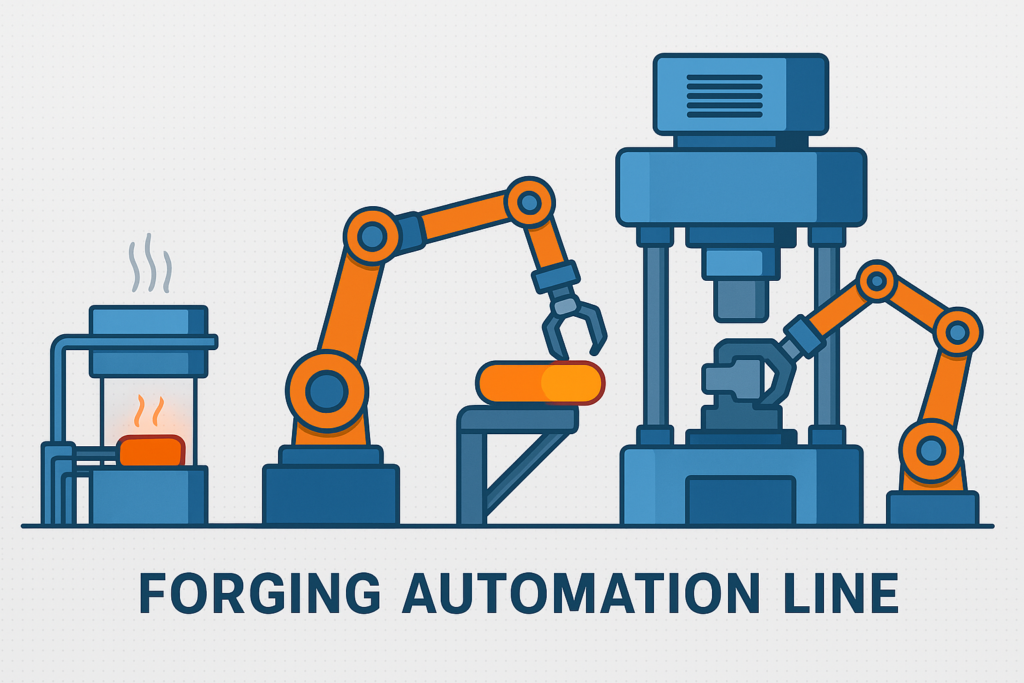

When we integrate industrial robots into forging lines, every step of the process is optimized:

Faster Billet Transfer – Robots can pick billets directly from induction or gas furnaces and place them in the press in seconds.

Precision Positioning – No human error; robots place billets exactly in the die cavity every time.

Reduced Heat Loss – Faster transfer means billets stay at optimal forging temperature, improving metallurgical properties.

Consistent Cycle Time – Robots don’t slow down; they maintain the same pace 24/7.

Multi-Operation Handling – Robots can feed billets for roughing, intermediate, and finishing operations without manual intervention.

In a typical closed die automotive component line, manual billet handling takes around 8–10 seconds between operations.

With robotic handling, this reduces to 3–5 seconds, which:

Cuts total cycle time by up to 40%

Increases daily production output significantly

Reduces heating energy consumption since billets remain hot

Shorter cycle time = less furnace holding time and reduced power/gas usage. Over a year, this translates to substantial cost savings, especially for high-volume production.

Robotic automation also extends tool life, as consistent billet placement reduces die wear and misalignment damage.

Forging involves extreme heat and heavy components. Robots remove the need for human operators to work in close proximity to hot metal and moving machinery, drastically reducing accident risks and improving workplace safety compliance.

We provide customized automation integration for:

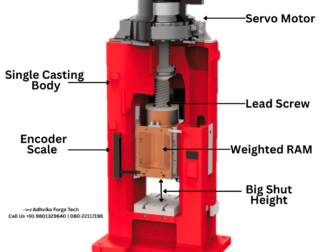

Electric Screw Presses (250–8500 ton)

Hydraulic Press Lines

Open Die Forging with Manipulators

Ring Rolling Machines

Special Purpose Forging Cells

Our turnkey automation solutions include robot selection, end-of-arm tooling design, PLC integration, safety enclosures, and complete commissioning – ensuring you get a ready-to-produce line from Day 1.

Robotic automation in forging is not a luxury anymore – it’s a necessity for industries looking to improve throughput, reduce costs, and enhance product quality. With Adhvika Forge Tech’s expertise, you can achieve precision forging, faster cycles, and higher ROI without compromising safety.

📞 Call Us: +91-9801329640 | 080-22117198

🌐 #ForgingSolutions | #ForgingAutomation | #ElectricScrewPress | #OpenDieForging | #ClosedDieForging | #RingRolling | #MetalForming | #Industry40 | #ForgingIndustry

| M | T | W | T | F | S | S |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |||

| 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| 19 | 20 | 21 | 22 | 23 | 24 | 25 |

| 26 | 27 | 28 | 29 | 30 | 31 | |

Scope of Forging Consultancy Services We offer comprehensive forging c

Screw Press for Titanium and Aluminum Screw Press for Titanium and Alu

Set up your complete forging line with expert consultant Amit Singh. F

India Best Young Forging Consultant Amit Singh

Electric Screw Press: Types, Benefits, Advantages, and Services Electr

Adhvika Forge Tech offers advanced Electric Screw Presses (250–8500

🇮🇳 Aluminum Alloy Forging आज भी भारत में �

Expert Forging Consultant Amit Singh specializes in Die Design, Forgin

Blog: The Art and Science of Forging: A Key Player in Manufacturing Ex

we specialize in providing end-to-end services for the installation an

Why Electric Screw Press Offers the Cheapest Forging Cost Introduction

We handle complete services for all types of forging presses, includin

Adhvika Forge Tech manufactures Direct Drive (DD) Forging Presses powe

Adhvika Forge Tech’s Bangalore factory delivers world-class forging

Join us at IMTEX FORMING 2026 and explore how Forging Consultant can h

Claw Pole Forging Solution – Complete Turnkey Process for Automob

Get expert Forging Consultancy Services from Forging Consultant – tu

High-performance materials like titanium, alloys & composites drive ae

Aluminum forging is a manufacturing process in which aluminum alloy is

Turnkey Solutions from design to production we gives you best Turnkey

Top 10 Electric Screw Press Brand & Manufacturers Top 10 Electric Scre

Automotive Drivetrains to Connect the Driveshaft to the Transmission o

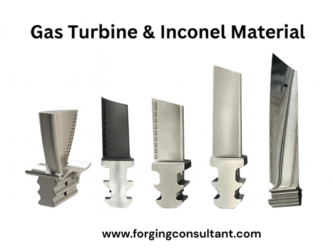

Inconel,Nimonic,Hastelloy,Nickel, Stellite Forging Solution

The cost of a 1000 Ton Electric Screw Press depends on whether you’r

Complete Hip Stem Forging Line Setup by Forging Consultant Precision F

Amit Singh is a leading forging consultant offering expertise in plant

Forging Consultant provides the best turnkey solutions for bombshell p

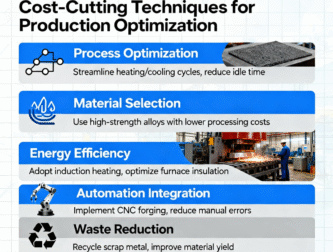

Cost-Cutting Techniques in Forging: Optimize Production Without Compro

Automation in forging with robots cuts cycle time by 40%, boosts outpu

Explore how 10 per kg forging rates are becoming the benchmark for ind

Open Die Forging Plant Setup – Inconel | Duplex | Super Duplex | Ste

How We Work – End-to-End Forging Solutions At Adhvika Forge Tech, le

630 Ton Electric Screw Press Price 630-ton Electric Screw Press avai

Why Choose a Forging Consultant? Are you planning to start or upgrade

Comparing Chinese and Indian screw presses in the forging industry inv

Compare forged vs cast bucket teeth: durability, wear resistance, cost

Aluminum Crown Forging Experts – Precision, Efficiency & Durabil

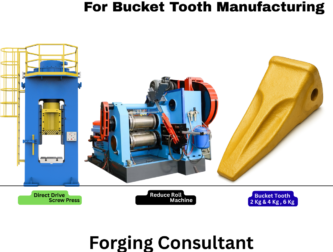

Complete Turnkey Solution for Bucket Tooth Manufacturing

Adhvika Forge Tech provides skilled forging manpower supply, covering

1️⃣ Material Selection Matters 🏗️ – Choosing the right allo

Aluminum and aluminum alloy forging involves shaping these materials t

Direct Drive Electric Screw Press – Energy saving, high precision &

At Forging Consultant, we provide turnkey solutions for closed die for

High-Strength Railway Forging Components – End-to-End Solutions for

Why Forging Consultant Services Are Essential for Your Business Runnin

The forging industry is evolving rapidly, with advancements in technol

In the dynamic and demanding world of forging, where precision, effici

Amit Singh – A Global Forging Consultant Changing the Future of Forg

India Best Supplier Hot Forging Press Top 10 AD Electric Screw Press &

Discover Amit Singh’s expertise in forging consultancy and turnk

The railway forging industry is evolving fast 🚆 — blending human

Forging Consultancy Group is proud to participate in Metal Forming Exp

A Ring Rolling Machine is used to manufacture hollow, ring-shaped comp

Shaping the Future of Forging with Vision, Experience & Innovation

Error: Contact form not found.