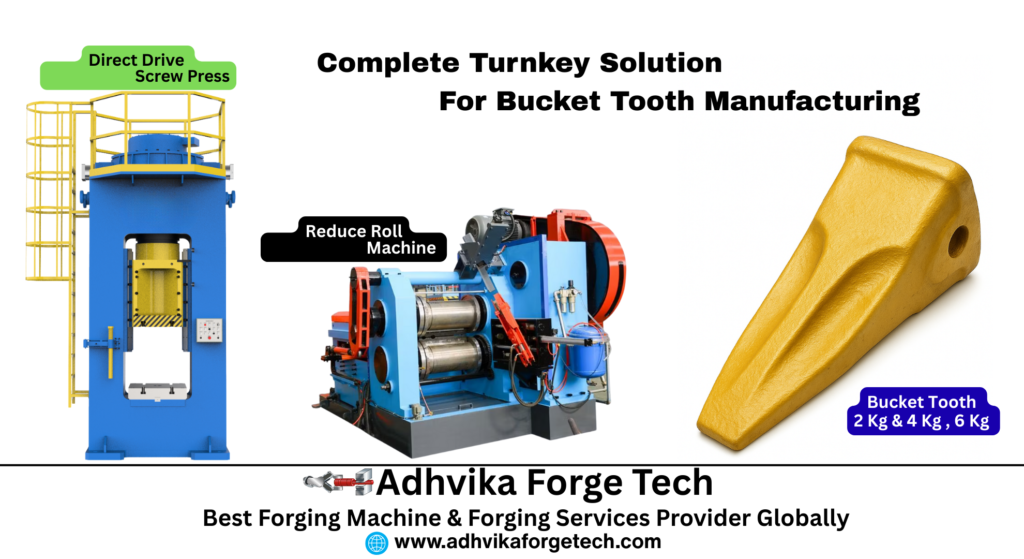

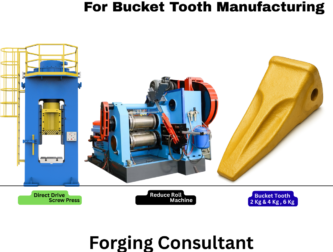

Forging Consultant offers complete turnkey bucket tooth manufacturing solutions – design, forging, heat treatment, machining & inspection for durable, high-quality parts.

Complete Turnkey Solution for Bucket Tooth Manufacturing – Forging Consultant Group

Bucket teeth are critical components used in heavy machinery for mining, excavation, and construction applications. They endure extreme wear and tear, high impact, and abrasive conditions, making precision forging, durability, and quality control essential for their performance and long service life.

Forging Consultant Group, we offer a complete turnkey solution for bucket tooth manufacturing, providing end-to-end services from conceptual design and raw material selection to final production, inspection, and delivery.

Our turnkey solution ensures that every stage of the manufacturing process is optimized for efficiency, cost-effectiveness, and product reliability. We understand that bucket teeth vary in size, shape, and material depending on their application, whether for excavators, loaders, or other heavy-duty machinery. Therefore, our approach is highly customized, integrating advanced forging technology, automation, and process control to deliver consistent, high-quality components.

Scope of Turnkey Solution:

Design & Engineering: Our engineering team works closely with customers to design bucket teeth according to machine specifications, operational load, and material properties. Using advanced CAD modeling and finite element analysis (FEA), we simulate stress distribution and wear patterns to optimize tooth geometry for maximum strength and longevity.

Material Selection: Depending on the application, we provide solutions using high-strength alloy steels, abrasion-resistant steels, and specialized materials. Material selection is critical to ensure the bucket teeth can withstand heavy impact, abrasion, and extreme working conditions.

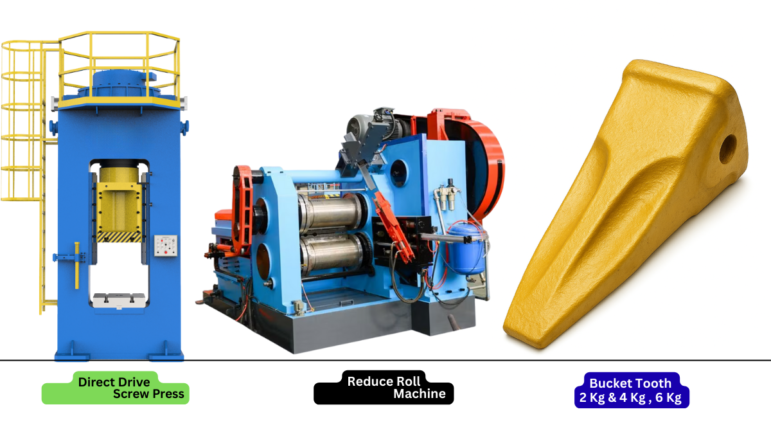

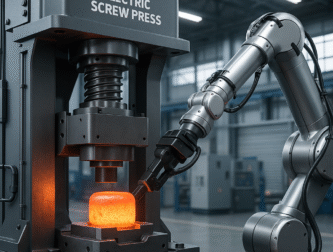

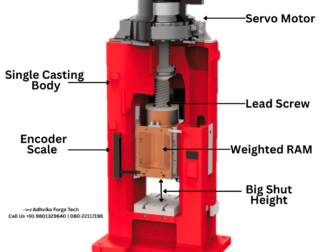

Forging Process: We utilize both open die and close die forging techniques, along with electric screw presses, hydraulic presses, and pneumatic hammers, to shape bucket teeth with precision. Our forging processes are designed to maximize material yield, reduce waste, and enhance grain flow, improving the mechanical properties and durability of the finished product.

Heat Treatment & Surface Hardening: After forging, bucket teeth undergo controlled heat treatment and surface hardening processes, including quenching and tempering, to achieve optimal hardness, toughness, and wear resistance. This ensures long-lasting performance even in the most demanding environments.

Machining & Finishing: Precision machining and finishing operations are performed to meet tight dimensional tolerances and ensure proper fitment with the base adapters and machinery. Our automated and semi-automated systems guarantee consistent quality and surface finish.

Quality Control & Testing: Every batch of bucket teeth undergoes stringent inspection and testing, including hardness tests, dimensional verification, and metallurgical analysis. We follow international standards to ensure that every component meets or exceeds customer expectations.

Automation & Production Line Integration: For high-volume production, we offer fully automated or semi-automated bucket tooth forging lines, including material handling systems, robotic manipulators, and quality inspection stations. This reduces manual intervention, minimizes cycle time, and ensures repeatable production quality.

Installation & Commissioning Support: Our turnkey solution includes complete installation, commissioning, and training for operators and maintenance personnel, ensuring smooth plant operations from day one. We provide technical support throughout the process to help customers achieve maximum productivity and efficiency.

Benefits of Choosing Forging Consultant Group Turnkey Solution:

End-to-end project management from design to delivery

High precision and consistent quality

Energy-efficient forging solutions

Reduced lead time and improved productivity

Expert technical support and after-sales service

Cost-effective and optimized material usage

With our Complete Turnkey Solution for Bucket Tooth Manufacturing, customers can transform their forging operations into high-efficiency, modern, and automated production units, ensuring superior product performance, long component life, and competitive advantage in the market. Forging Consultant Group combines decades of industry experience, technical expertise, and innovative solutions to provide unmatched value for forging businesses worldwide.

#BucketToothManufacturing #TurnkeyForgingSolution #ForgingConsultantGroup #ForgingAutomation #HeavyDutyForging #IndustrialForging #HighPrecisionForging #MiningEquipmentComponents #MaterialOptimization #ForgingConsultant

| M | T | W | T | F | S | S |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |||

| 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| 19 | 20 | 21 | 22 | 23 | 24 | 25 |

| 26 | 27 | 28 | 29 | 30 | 31 | |

Scope of Forging Consultancy Services We offer comprehensive forging c

Screw Press for Titanium and Aluminum Screw Press for Titanium and Alu

Set up your complete forging line with expert consultant Amit Singh. F

India Best Young Forging Consultant Amit Singh

Electric Screw Press: Types, Benefits, Advantages, and Services Electr

Adhvika Forge Tech offers advanced Electric Screw Presses (250–8500

🇮🇳 Aluminum Alloy Forging आज भी भारत में �

Expert Forging Consultant Amit Singh specializes in Die Design, Forgin

Blog: The Art and Science of Forging: A Key Player in Manufacturing Ex

we specialize in providing end-to-end services for the installation an

Why Electric Screw Press Offers the Cheapest Forging Cost Introduction

We handle complete services for all types of forging presses, includin

Adhvika Forge Tech manufactures Direct Drive (DD) Forging Presses powe

Adhvika Forge Tech’s Bangalore factory delivers world-class forging

Join us at IMTEX FORMING 2026 and explore how Forging Consultant can h

Claw Pole Forging Solution – Complete Turnkey Process for Automob

Get expert Forging Consultancy Services from Forging Consultant – tu

High-performance materials like titanium, alloys & composites drive ae

Aluminum forging is a manufacturing process in which aluminum alloy is

Turnkey Solutions from design to production we gives you best Turnkey

Top 10 Electric Screw Press Brand & Manufacturers Top 10 Electric Scre

Automotive Drivetrains to Connect the Driveshaft to the Transmission o

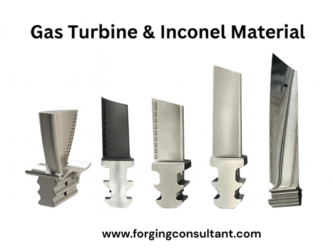

Inconel,Nimonic,Hastelloy,Nickel, Stellite Forging Solution

The cost of a 1000 Ton Electric Screw Press depends on whether you’r

Complete Hip Stem Forging Line Setup by Forging Consultant Precision F

Amit Singh is a leading forging consultant offering expertise in plant

Forging Consultant provides the best turnkey solutions for bombshell p

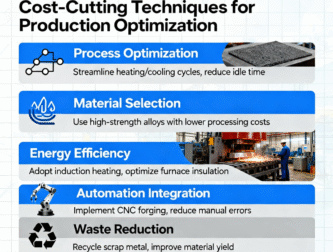

Cost-Cutting Techniques in Forging: Optimize Production Without Compro

Automation in forging with robots cuts cycle time by 40%, boosts outpu

Explore how 10 per kg forging rates are becoming the benchmark for ind

Open Die Forging Plant Setup – Inconel | Duplex | Super Duplex | Ste

How We Work – End-to-End Forging Solutions At Adhvika Forge Tech, le

630 Ton Electric Screw Press Price 630-ton Electric Screw Press avai

Why Choose a Forging Consultant? Are you planning to start or upgrade

Comparing Chinese and Indian screw presses in the forging industry inv

Compare forged vs cast bucket teeth: durability, wear resistance, cost

Aluminum Crown Forging Experts – Precision, Efficiency & Durabil

Complete Turnkey Solution for Bucket Tooth Manufacturing

Adhvika Forge Tech provides skilled forging manpower supply, covering

1️⃣ Material Selection Matters 🏗️ – Choosing the right allo

Aluminum and aluminum alloy forging involves shaping these materials t

Direct Drive Electric Screw Press – Energy saving, high precision &

At Forging Consultant, we provide turnkey solutions for closed die for

High-Strength Railway Forging Components – End-to-End Solutions for

Why Forging Consultant Services Are Essential for Your Business Runnin

The forging industry is evolving rapidly, with advancements in technol

In the dynamic and demanding world of forging, where precision, effici

Amit Singh – A Global Forging Consultant Changing the Future of Forg

India Best Supplier Hot Forging Press Top 10 AD Electric Screw Press &

Discover Amit Singh’s expertise in forging consultancy and turnk

The railway forging industry is evolving fast 🚆 — blending human

Forging Consultancy Group is proud to participate in Metal Forming Exp

A Ring Rolling Machine is used to manufacture hollow, ring-shaped comp

Shaping the Future of Forging with Vision, Experience & Innovation

Error: Contact form not found.