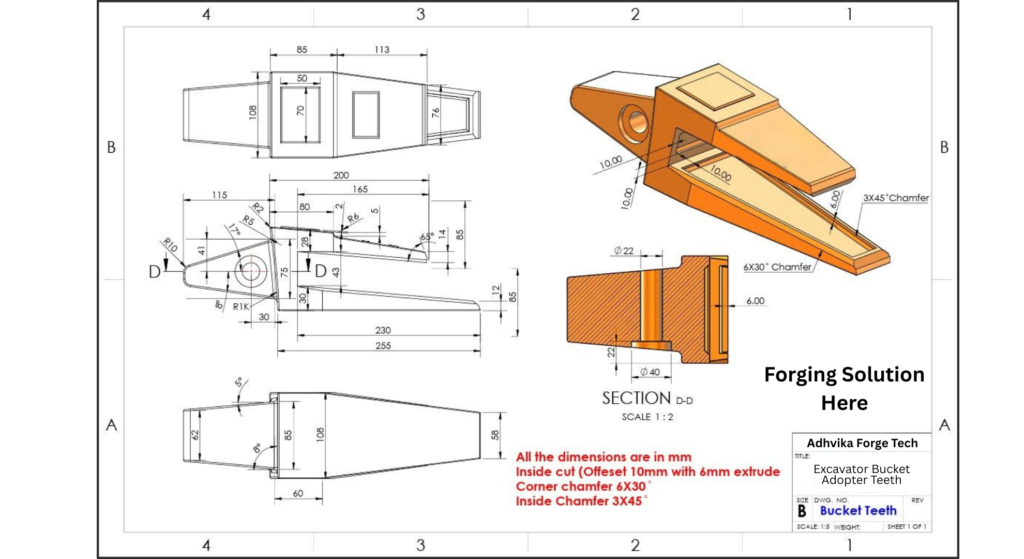

Forging Consultant Group, we provide comprehensive forging solutions for Excavator Bucket Adopter Teeth, catering to industries requiring high-strength, durable components for heavy machinery. Our expertise spans the complete production cycle—from material selection, forging, heat treatment, machining, to final inspection and delivery—ensuring top-quality products suitable for global OEMs and aftermarket suppliers.

Excavator Bucket Adopter Teeth are critical components in construction and mining equipment, designed to endure extreme wear, high impact, and abrasive conditions. These components are responsible for enhancing the penetration efficiency and operational life of excavator buckets. At Forging Consultant Group, we understand the importance of precision forging and robust metallurgy to deliver components that can perform reliably under rigorous working conditions.

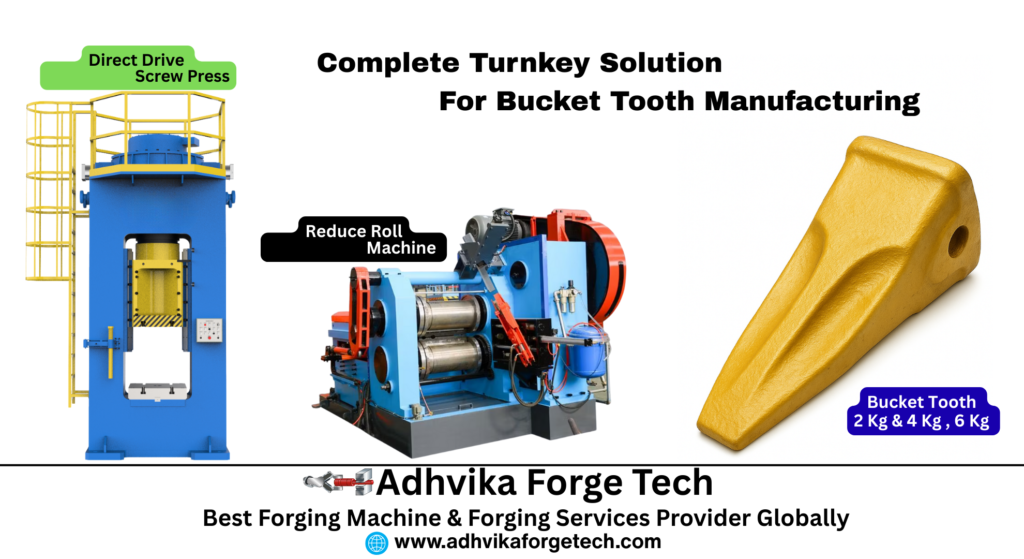

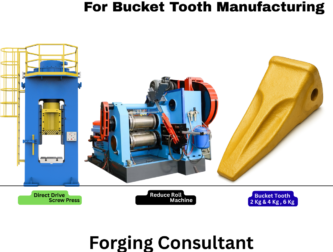

Weight Range: 2 kg to 40 kg per component, accommodating small to large bucket sizes.

Material Options: High-strength alloy steels and wear-resistant materials suitable for abrasive environments.

Forging Technology: Closed-die forging ensures optimal grain flow, structural integrity, and superior strength.

Heat Treatment: Controlled processes to achieve maximum hardness, toughness, and wear resistance while minimizing distortion.

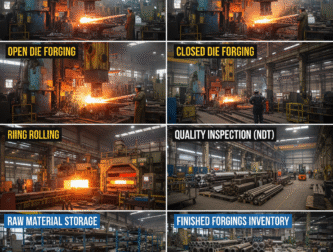

Material Selection: We source certified alloy steels capable of withstanding high impact and abrasive wear.

Cutting & Preform Preparation: Billets are accurately cut to size, ensuring minimal waste and uniform material distribution.

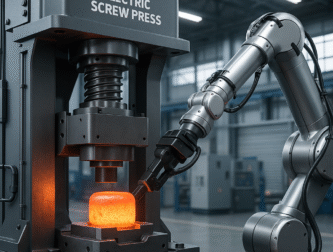

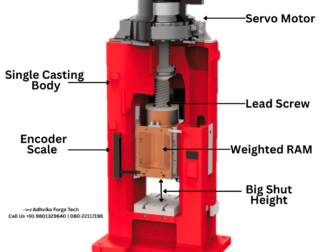

Forging Operations: Using electric screw presses, hydraulic presses, and open-die forging techniques, we shape the preforms into the required geometry with precise metal flow and grain orientation.

Heat Treatment: Components undergo quenching and tempering cycles to achieve the desired hardness and mechanical properties for long-term durability.

Machining & Finishing: Post-forging operations include surface finishing, drilling, and profiling for proper fitment on the bucket assembly.

Quality Inspection: Each component is inspected for dimensional accuracy, hardness, microstructure, and NDT checks ensuring compliance with OEM standards.

Our Excavator Bucket Adopter Teeth are used by leading construction equipment manufacturers worldwide, including:

JCB India – Known for robust and versatile construction machinery.

Caterpillar Inc. (USA) – Renowned for heavy-duty earthmoving equipment.

Komatsu Ltd. (Japan) – Leading in hydraulic excavators and mining equipment.

Hitachi Construction Machinery (Japan) – High-performance excavators for construction and mining.

Volvo Construction Equipment (Sweden) – Durable and precision-engineered machines.

Doosan Infracore (DEVELON, South Korea) – Global provider of construction machinery.

Liebherr Group (Germany) – Premium engineering and heavy-duty equipment manufacturer.

SANY Group (China) – Known for large-scale construction and mining equipment.

Hyundai Construction Equipment (South Korea) – Innovative solutions for construction and earthmoving industries.

These partnerships and OEM compatibilities demonstrate our ability to meet international standards, maintain consistent quality, and supply components that integrate seamlessly into global machinery.

Complete Turnkey Solution: From forging to final delivery, we handle the entire production cycle.

Precision Engineering: Our processes ensure high dimensional accuracy, optimal metal flow, and superior mechanical properties.

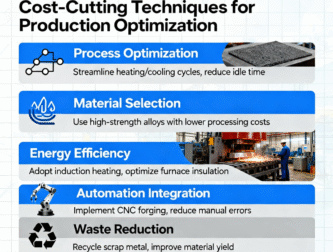

Material & Cost Efficiency: We optimize material usage and process parameters to deliver cost-effective solutions without compromising quality.

Global Standards Compliance: Our components adhere to ISO and OEM quality standards, ensuring reliability and longevity.

Scalable Production: Capable of delivering high-volume orders while maintaining consistent quality across all components.

With decades of combined experience in the forging industry, Forging Consultant Group continues to be a trusted supplier for global brands and construction companies. Our technical expertise, advanced machinery, and skilled workforce enable us to deliver Excavator Bucket Adopter Teeth that maximize operational efficiency and minimize downtime, ensuring our clients get the best value for their investment.

Whether you require 2 kg precision teeth for small excavators or 40 kg heavy-duty teeth for large-scale machinery, Forging Consultant Group provides reliable, durable, and high-performance forging solutions tailored to your specific needs.

| M | T | W | T | F | S | S |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |||

| 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| 19 | 20 | 21 | 22 | 23 | 24 | 25 |

| 26 | 27 | 28 | 29 | 30 | 31 | |

Scope of Forging Consultancy Services We offer comprehensive forging c

Screw Press for Titanium and Aluminum Screw Press for Titanium and Alu

Set up your complete forging line with expert consultant Amit Singh. F

India Best Young Forging Consultant Amit Singh

Electric Screw Press: Types, Benefits, Advantages, and Services Electr

Adhvika Forge Tech offers advanced Electric Screw Presses (250–8500

🇮🇳 Aluminum Alloy Forging आज भी भारत में �

Expert Forging Consultant Amit Singh specializes in Die Design, Forgin

Blog: The Art and Science of Forging: A Key Player in Manufacturing Ex

we specialize in providing end-to-end services for the installation an

Why Electric Screw Press Offers the Cheapest Forging Cost Introduction

We handle complete services for all types of forging presses, includin

Adhvika Forge Tech manufactures Direct Drive (DD) Forging Presses powe

Adhvika Forge Tech’s Bangalore factory delivers world-class forging

Join us at IMTEX FORMING 2026 and explore how Forging Consultant can h

Claw Pole Forging Solution – Complete Turnkey Process for Automob

Get expert Forging Consultancy Services from Forging Consultant – tu

High-performance materials like titanium, alloys & composites drive ae

Aluminum forging is a manufacturing process in which aluminum alloy is

Turnkey Solutions from design to production we gives you best Turnkey

Top 10 Electric Screw Press Brand & Manufacturers Top 10 Electric Scre

Automotive Drivetrains to Connect the Driveshaft to the Transmission o

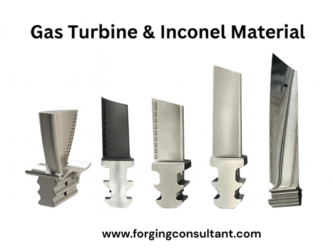

Inconel,Nimonic,Hastelloy,Nickel, Stellite Forging Solution

The cost of a 1000 Ton Electric Screw Press depends on whether you’r

Complete Hip Stem Forging Line Setup by Forging Consultant Precision F

Amit Singh is a leading forging consultant offering expertise in plant

Forging Consultant provides the best turnkey solutions for bombshell p

Cost-Cutting Techniques in Forging: Optimize Production Without Compro

Automation in forging with robots cuts cycle time by 40%, boosts outpu

Explore how 10 per kg forging rates are becoming the benchmark for ind

Open Die Forging Plant Setup – Inconel | Duplex | Super Duplex | Ste

How We Work – End-to-End Forging Solutions At Adhvika Forge Tech, le

630 Ton Electric Screw Press Price 630-ton Electric Screw Press avai

Why Choose a Forging Consultant? Are you planning to start or upgrade

Comparing Chinese and Indian screw presses in the forging industry inv

Compare forged vs cast bucket teeth: durability, wear resistance, cost

Aluminum Crown Forging Experts – Precision, Efficiency & Durabil

Complete Turnkey Solution for Bucket Tooth Manufacturing

Adhvika Forge Tech provides skilled forging manpower supply, covering

1️⃣ Material Selection Matters 🏗️ – Choosing the right allo

Aluminum and aluminum alloy forging involves shaping these materials t

Direct Drive Electric Screw Press – Energy saving, high precision &

At Forging Consultant, we provide turnkey solutions for closed die for

High-Strength Railway Forging Components – End-to-End Solutions for

Why Forging Consultant Services Are Essential for Your Business Runnin

The forging industry is evolving rapidly, with advancements in technol

In the dynamic and demanding world of forging, where precision, effici

Amit Singh – A Global Forging Consultant Changing the Future of Forg

India Best Supplier Hot Forging Press Top 10 AD Electric Screw Press &

Discover Amit Singh’s expertise in forging consultancy and turnk

The railway forging industry is evolving fast 🚆 — blending human

Forging Consultancy Group is proud to participate in Metal Forming Exp

A Ring Rolling Machine is used to manufacture hollow, ring-shaped comp

Shaping the Future of Forging with Vision, Experience & Innovation

Error: Contact form not found.