The aerospace sector has always been at the forefront of technological innovation, and one of the key driving forces behind its evolution is the continuous development and application of high-performance materials. Aircrafts, spacecrafts, and defense systems demand materials that can withstand extreme conditions such as high pressure, elevated temperatures, and dynamic stresses, while also delivering superior strength-to-weight ratios. This requirement has fueled a massive demand for materials like titanium alloys, aluminum alloys, nickel-based superalloys, and advanced composites.

One of the critical challenges in aerospace manufacturing is achieving the right balance between durability, lightweight design, and fuel efficiency. Every kilogram saved in an aircraft structure directly translates to lower fuel consumption, reduced emissions, and improved operational efficiency. High-performance materials such as carbon fiber-reinforced polymers (CFRP) are increasingly being used in fuselage sections, wings, and rotor blades to achieve weight savings without compromising on structural integrity.

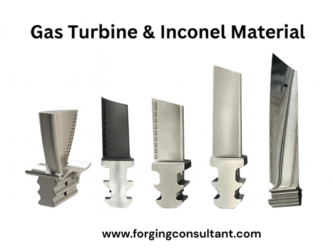

Titanium alloys are another cornerstone in aerospace manufacturing. Known for their excellent strength-to-weight ratio, resistance to corrosion, and ability to perform well under high-temperature environments, titanium is extensively used in engine components, landing gears, and critical structural parts. Similarly, nickel-based superalloys play a crucial role in jet engine turbines, where components are exposed to extreme heat and mechanical loads. These alloys maintain their mechanical strength and oxidation resistance at temperatures where other materials fail, making them indispensable for modern propulsion systems.

The rise of electric aircraft and space exploration programs is further accelerating the demand for advanced materials. As the industry moves towards greener technologies, manufacturers require lightweight yet thermally stable materials to house batteries, electric drives, and hybrid propulsion units. Additive manufacturing (3D printing) is also reshaping the way aerospace parts are designed and produced, enabling the creation of complex geometries with minimal waste, while using high-performance alloys tailored for specific applications.

Beyond mechanical performance, sustainability is becoming a central focus. Aerospace companies are investing in recyclable composites, eco-friendly alloys, and energy-efficient production methods to reduce the environmental impact of manufacturing. This aligns with global aviation goals to achieve net-zero emissions by 2050.

In defense applications, high-performance materials provide critical advantages in producing lightweight armored vehicles, high-speed missiles, and stealth aircraft. The ability of these materials to withstand harsh operational environments while ensuring safety and reliability makes them indispensable.

Looking ahead, the global aerospace material market is expected to witness significant growth as countries invest heavily in defense modernization, commercial aviation expansion, and space exploration missions. Companies that can deliver cost-effective, high-strength, and sustainable material solutions will play a pivotal role in shaping the future of aerospace engineering.

In conclusion, the aerospace sector’s progress is inseparably tied to innovations in material science. High-performance materials are not just enablers of technology but also catalysts for efficiency, sustainability, and safety. From lightweight composites in commercial aircraft to superalloys in jet engines, the future of flight depends on materials that can perform beyond the ordinary.

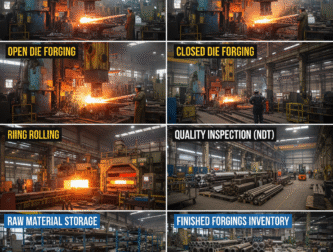

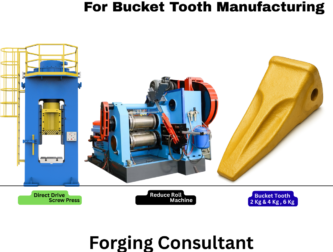

Call us your trusted forging consultant! 🔧 Amit Singh & Adhvika Forge Tech provide turnkey solutions in Open Die & Close Die forging, from press selection to production. With 100+ years of team expertise, we deliver precision, low-cost solutions & global support. #adhvikaforgetech #forging

| M | T | W | T | F | S | S |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |||

| 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| 19 | 20 | 21 | 22 | 23 | 24 | 25 |

| 26 | 27 | 28 | 29 | 30 | 31 | |

Scope of Forging Consultancy Services We offer comprehensive forging c

Screw Press for Titanium and Aluminum Screw Press for Titanium and Alu

Set up your complete forging line with expert consultant Amit Singh. F

India Best Young Forging Consultant Amit Singh

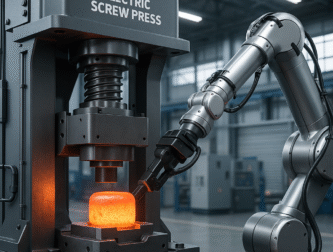

Electric Screw Press: Types, Benefits, Advantages, and Services Electr

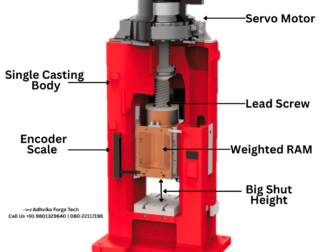

Adhvika Forge Tech offers advanced Electric Screw Presses (250–8500

🇮🇳 Aluminum Alloy Forging आज भी भारत में �

Expert Forging Consultant Amit Singh specializes in Die Design, Forgin

Blog: The Art and Science of Forging: A Key Player in Manufacturing Ex

we specialize in providing end-to-end services for the installation an

Why Electric Screw Press Offers the Cheapest Forging Cost Introduction

We handle complete services for all types of forging presses, includin

Adhvika Forge Tech manufactures Direct Drive (DD) Forging Presses powe

Adhvika Forge Tech’s Bangalore factory delivers world-class forging

Join us at IMTEX FORMING 2026 and explore how Forging Consultant can h

Claw Pole Forging Solution – Complete Turnkey Process for Automob

Get expert Forging Consultancy Services from Forging Consultant – tu

High-performance materials like titanium, alloys & composites drive ae

Aluminum forging is a manufacturing process in which aluminum alloy is

Turnkey Solutions from design to production we gives you best Turnkey

Top 10 Electric Screw Press Brand & Manufacturers Top 10 Electric Scre

Automotive Drivetrains to Connect the Driveshaft to the Transmission o

Inconel,Nimonic,Hastelloy,Nickel, Stellite Forging Solution

The cost of a 1000 Ton Electric Screw Press depends on whether you’r

Complete Hip Stem Forging Line Setup by Forging Consultant Precision F

Amit Singh is a leading forging consultant offering expertise in plant

Forging Consultant provides the best turnkey solutions for bombshell p

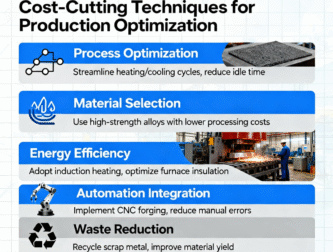

Cost-Cutting Techniques in Forging: Optimize Production Without Compro

Automation in forging with robots cuts cycle time by 40%, boosts outpu

Explore how 10 per kg forging rates are becoming the benchmark for ind

Open Die Forging Plant Setup – Inconel | Duplex | Super Duplex | Ste

How We Work – End-to-End Forging Solutions At Adhvika Forge Tech, le

630 Ton Electric Screw Press Price 630-ton Electric Screw Press avai

Why Choose a Forging Consultant? Are you planning to start or upgrade

Comparing Chinese and Indian screw presses in the forging industry inv

Compare forged vs cast bucket teeth: durability, wear resistance, cost

Aluminum Crown Forging Experts – Precision, Efficiency & Durabil

Complete Turnkey Solution for Bucket Tooth Manufacturing

Adhvika Forge Tech provides skilled forging manpower supply, covering

1️⃣ Material Selection Matters 🏗️ – Choosing the right allo

Aluminum and aluminum alloy forging involves shaping these materials t

Direct Drive Electric Screw Press – Energy saving, high precision &

At Forging Consultant, we provide turnkey solutions for closed die for

High-Strength Railway Forging Components – End-to-End Solutions for

Why Forging Consultant Services Are Essential for Your Business Runnin

The forging industry is evolving rapidly, with advancements in technol

In the dynamic and demanding world of forging, where precision, effici

Amit Singh – A Global Forging Consultant Changing the Future of Forg

India Best Supplier Hot Forging Press Top 10 AD Electric Screw Press &

Discover Amit Singh’s expertise in forging consultancy and turnk

The railway forging industry is evolving fast 🚆 — blending human

Forging Consultancy Group is proud to participate in Metal Forming Exp

A Ring Rolling Machine is used to manufacture hollow, ring-shaped comp

Shaping the Future of Forging with Vision, Experience & Innovation

Error: Contact form not found.