Top 10 Electric Screw Press brands & manufacturers include Adhvika Forge Tech for precision, energy efficiency, and high-performance forging solutions.

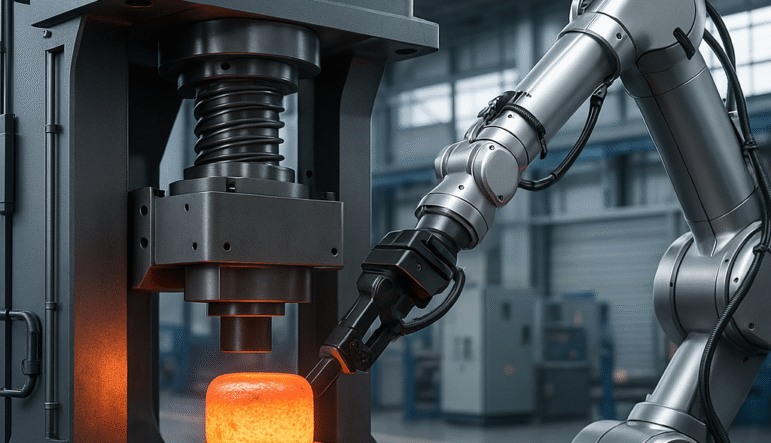

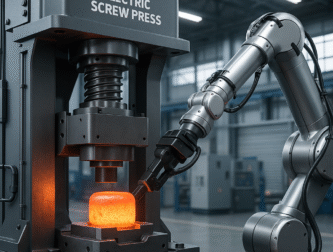

The forging industry is evolving rapidly with the demand for precision, high-speed, and energy-efficient production. At the heart of this transformation is the Electric Screw Press, a versatile and powerful forging solution that ensures high-quality output with minimal energy consumption. These presses are ideal for automotive, aerospace, defense, and general engineering industries. Among the top global manufacturers of electric screw presses, Adhvika Forge Tech Pvt. Ltd. stands out as a leader, providing Direct Drive Screw Presses, Servo Drive-Based Screw Presses, and turnkey forging solutions.

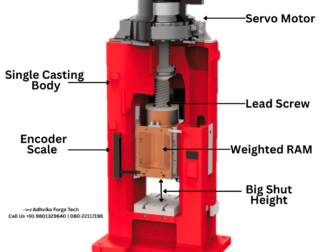

Adhvika Forge Tech has emerged as a premium manufacturer and consultant for electric screw presses in India and globally. With their advanced Direct Drive Screw Press and Servo Drive-Based Screw Press solutions, Adhvika ensures:

High precision forging of automotive, aerospace, and defense components.

Energy-efficient operations with ABB/Siemens inverter drives.

Low maintenance costs and superior die life.

Turnkey solutions from press selection to production line commissioning.

Global support and on-site training for customers.

Their presses range from 250 tons to 8500 tons, catering to light alloy forgings, titanium, aluminum, and heavy steel components. The Direct Drive Electric Screw Press integrates motor and screw directly, reducing mechanical losses, providing stable energy transfer, and enabling high repeatability. Meanwhile, the Servo Drive-Based Screw Press allows programmable stroke profiles, precise speed control, and adaptive forging pressure, making it ideal for complex component geometries.

Anyang Forging Press is known for its J58K Series Electric Screw Presses. These presses are widely used in precision die forging and large-scale industrial operations. Their features include high-speed operation, robust frame construction, and long service life. They are widely adopted in automotive and heavy equipment forging industries.

Newwish specializes in CNC Electric Screw Presses with full automation capabilities. Their presses are designed for high-tonnage die forging, offering:

Servo-controlled motion for complex component shaping.

Energy-efficient drives.

Integrated sensors for monitoring load and die stress.

They are particularly strong in automotive and aerospace forging solutions, providing fully automated production lines.

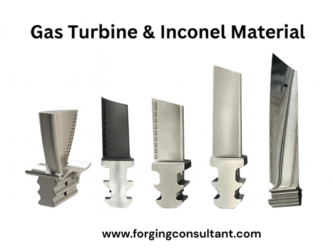

Yadon Press manufactures servo direct drive electric screw presses with precision engineering. Their presses combine efficiency with flexibility, making them suitable for aerospace alloys, stainless steels, and titanium components. Yadon focuses on minimizing energy consumption while maximizing forging quality and die life.

Haloong Machinery produces high-tonnage electric screw presses, including 1000T models, suitable for large-scale industrial forging. They incorporate servo motor driving systems, offering precise control, repeatability, and adaptability for various forging shapes and alloys.

A globally recognized leader in forming technology, Schuler provides direct drive screw presses known for reliability and flexibility. Schuler presses are widely used in the automotive, aerospace, and energy sectors. Their advanced control systems enable:

Adaptive stroke control.

High energy efficiency.

Reduced wear on dies and mechanical components.

HIWIN is well known for precision linear motion components, and their screw press systems integrate multi-axis servo controls for advanced metal forming. They specialize in high-precision, low-deflection operations, making them ideal for aerospace and fine automotive components.

Allied Machinery offers a wide range of screw presses with capabilities for rebuilds, retrofits, and upgrades. They focus on improving existing presses with modern servo drives and energy-efficient motors, extending machine life and reducing operational costs.

Trident TNZ manufactures screw presses for industrial applications, including forging and wastewater processing. Their presses feature:

Robust construction for continuous operation.

Servo drive options for energy optimization.

Adaptive motion control for precise forming.

Although HUBER is famous for Q-PRESS® sludge dewatering, their expertise extends to precision screw presses for metal and industrial applications. They focus on high efficiency, durability, and precise load control.

High Precision & Efficiency: Direct drive and servo drives provide maximum energy transfer with minimal loss, ensuring consistent die filling and reduced scrap.

Energy Savings: Inverter-based motors reduce energy consumption up to 40% compared to traditional mechanical presses.

Low Maintenance: Reduced mechanical components in direct drive systems result in fewer failures and longer service intervals.

Global Support & Consultancy: As a full-service provider, Adhvika supports press selection, foundation design, line automation, and process optimization.

Custom Solutions: Capable of handling titanium, aluminum alloys, high-strength steels, and complex automotive or aerospace components.

Automotive: Axle shafts, high-tensile bolts, steering components.

Aerospace: Titanium landing gear parts, engine brackets, wing components.

Defense: Armor components, structural frames, shafts.

Industrial: Valves, flanges, bearings, and high-precision components.

The Electric Screw Press remains a cornerstone of modern forging technology. From high-speed automotive forging to precise aerospace components, the integration of Direct Drive and Servo Drive-Based Screw Presses ensures unmatched precision, energy efficiency, and operational reliability. Among global leaders, Adhvika Forge Tech distinguishes itself by offering complete solutions, combining world-class technology with local expertise, making it the go-to partner for industries seeking turnkey forging solutions.

Contact Adhvika Forge Tech today to explore advanced forging presses, direct drive, and servo-driven solutions to optimize your production and reduce operational costs.

#AdhvikaForgeTech #ElectricScrewPress #DirectDrivePress #ServoDrivePress #ForgingSolution #AutomotiveForging #AerospaceForging #DefenseForging #PrecisionForging #TurnkeyForgingSolution

| M | T | W | T | F | S | S |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |||

| 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| 19 | 20 | 21 | 22 | 23 | 24 | 25 |

| 26 | 27 | 28 | 29 | 30 | 31 | |

Scope of Forging Consultancy Services We offer comprehensive forging c

Screw Press for Titanium and Aluminum Screw Press for Titanium and Alu

Set up your complete forging line with expert consultant Amit Singh. F

India Best Young Forging Consultant Amit Singh

Electric Screw Press: Types, Benefits, Advantages, and Services Electr

Adhvika Forge Tech offers advanced Electric Screw Presses (250–8500

🇮🇳 Aluminum Alloy Forging आज भी भारत में �

Expert Forging Consultant Amit Singh specializes in Die Design, Forgin

Blog: The Art and Science of Forging: A Key Player in Manufacturing Ex

we specialize in providing end-to-end services for the installation an

Why Electric Screw Press Offers the Cheapest Forging Cost Introduction

We handle complete services for all types of forging presses, includin

Adhvika Forge Tech manufactures Direct Drive (DD) Forging Presses powe

Adhvika Forge Tech’s Bangalore factory delivers world-class forging

Join us at IMTEX FORMING 2026 and explore how Forging Consultant can h

Claw Pole Forging Solution – Complete Turnkey Process for Automob

Get expert Forging Consultancy Services from Forging Consultant – tu

High-performance materials like titanium, alloys & composites drive ae

Aluminum forging is a manufacturing process in which aluminum alloy is

Turnkey Solutions from design to production we gives you best Turnkey

Top 10 Electric Screw Press Brand & Manufacturers Top 10 Electric Scre

Automotive Drivetrains to Connect the Driveshaft to the Transmission o

Inconel,Nimonic,Hastelloy,Nickel, Stellite Forging Solution

The cost of a 1000 Ton Electric Screw Press depends on whether you’r

Complete Hip Stem Forging Line Setup by Forging Consultant Precision F

Amit Singh is a leading forging consultant offering expertise in plant

Forging Consultant provides the best turnkey solutions for bombshell p

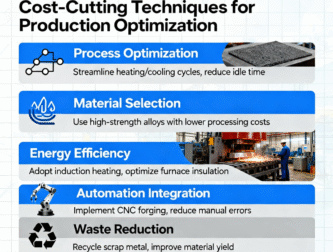

Cost-Cutting Techniques in Forging: Optimize Production Without Compro

Automation in forging with robots cuts cycle time by 40%, boosts outpu

Explore how 10 per kg forging rates are becoming the benchmark for ind

Open Die Forging Plant Setup – Inconel | Duplex | Super Duplex | Ste

How We Work – End-to-End Forging Solutions At Adhvika Forge Tech, le

630 Ton Electric Screw Press Price 630-ton Electric Screw Press avai

Why Choose a Forging Consultant? Are you planning to start or upgrade

Comparing Chinese and Indian screw presses in the forging industry inv

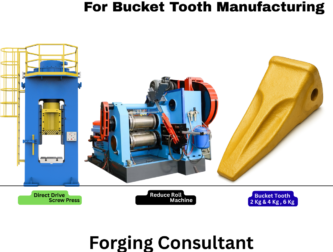

Compare forged vs cast bucket teeth: durability, wear resistance, cost

Aluminum Crown Forging Experts – Precision, Efficiency & Durabil

Complete Turnkey Solution for Bucket Tooth Manufacturing

Adhvika Forge Tech provides skilled forging manpower supply, covering

1️⃣ Material Selection Matters 🏗️ – Choosing the right allo

Aluminum and aluminum alloy forging involves shaping these materials t

Direct Drive Electric Screw Press – Energy saving, high precision &

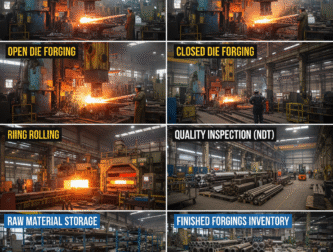

At Forging Consultant, we provide turnkey solutions for closed die for

High-Strength Railway Forging Components – End-to-End Solutions for

Why Forging Consultant Services Are Essential for Your Business Runnin

The forging industry is evolving rapidly, with advancements in technol

In the dynamic and demanding world of forging, where precision, effici

Amit Singh – A Global Forging Consultant Changing the Future of Forg

India Best Supplier Hot Forging Press Top 10 AD Electric Screw Press &

Discover Amit Singh’s expertise in forging consultancy and turnk

The railway forging industry is evolving fast 🚆 — blending human

Forging Consultancy Group is proud to participate in Metal Forming Exp

A Ring Rolling Machine is used to manufacture hollow, ring-shaped comp

Shaping the Future of Forging with Vision, Experience & Innovation

Error: Contact form not found.