Forging Consultant Group provides complete automobile axle shaft forging solutions, including heating, upsetting, and rotary forging. We specialize in spline shafts and axle shafts for heavy commercial trucks and lightweight vehicles, delivering high precision, strength, and reliability. Our turnkey solutions cover the entire forging process, ensuring efficient production, minimal scrap, and faster ROI for clients globally.

Forging Consultant Group – Your Partner for Precision Forgings

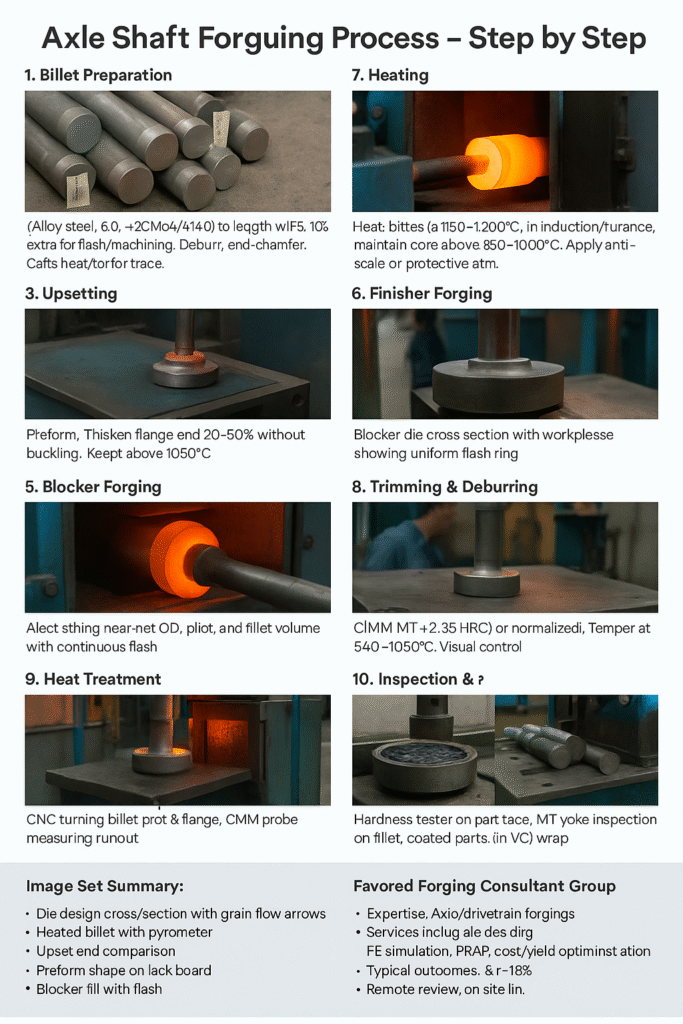

Material: Alloy steel (e.g., 42CrMo4/4140)

Process: Cut to length + 5–10% extra for flash/machining, deburr, chamfer ends, verify chemistry/UT.

Key: Straight, clean surface avoids laps/non-fill.

Traceability: Mark heat/lot.

Image Prompt: “Cut alloy-steel billets with ID tags and chamfered ends on a workshop table, high-detail, realistic lighting.”

Temp: 1150–1200°C (induction/furnace), maintain core above 950–1000°C.

Protection: Anti-scale or protective atmosphere.

Image Prompt: “Billet glowing orange in furnace, IR pyrometer reading visible, light anti-scale coat applied, industrial background.”

Goal: Thicken flange end 30–50% without buckling.

Lubrication: Graphite or high-temp lubricant.

Temp: Keep above 1050°C.

Image Prompt: “Hot billet being upset by press, showing before-and-after flange height, industrial press view.”

Shape: Disk-like flange + tapered neck, balance material for blocker fill, maintain fillet stock.

Image Prompt: “Preform with distinct flange disk and neck profile on layout board with gauges, top view.”

Action: Achieve near-net OD, pilot, and fillet volume with continuous flash.

Die Temp: 200–300°C.

Image Prompt: “Blocker die cross-section with workpiece showing uniform flash ring, industrial die setup.”

Objective: Final bolt face, hub thickness, radii, light coining if needed.

Temp: Above 1000–1050°C.

Image Prompt: “Finisher die closed on workpiece; ejected part with crisp features, industrial lighting.”

Operations: Hot-trim flash, shotblast, deburr, pierce as required.

Key: Maintain flatness, rim integrity.

Image Prompt: “Trimming press removing flash ring; trimmed part on table, operator in background.”

Type: Quench & temper (4140 → 28–36 HRC) or normalize.

Temp: Temper at 540–650°C; control distortion.

Image Prompt: “Basket of billets entering furnace; microstructure inset showing tempered martensite.”

Datum: Pilot & bolt face.

Operations: Turn pilot OD, face flange, drill/ream bolt circle, chamfer holes.

Inspection: CMM for runout, surface finish Ra 1.6–3.2 µm.

Image Prompt: “CNC turning billet pilot and flange, CMM probe measuring runout, workshop background.”

Checks: CMM, MT, hardness mapping, visual for laps/underfill.

Protection: Phosphate + oil or VCI wrap. Mark part number & heat code.

Image Prompt: “Hardness tester on face, MT yoke inspection on fillet, coated parts in VCI wrap.”

Die design cross-section with grain flow arrows

Heated billet with pyrometer

Upset end comparison

Preform shape on layout board

Blocker fill with flash

Finisher strike result

Trimming operation

Heat-treat furnace and micrograph

CNC machining with CMM probe

MT inspection and coated parts

Expertise: Axle/drivetrain forgings

Services: Die design, FE simulation, PPAP, cost/yield optimization

Benefits: 8–15% flash reduction, 20–30% die-life gains, improved first-pass yield

Engagement: Remote review, on-site line study, three-run tryout

| M | T | W | T | F | S | S |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |||

| 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| 19 | 20 | 21 | 22 | 23 | 24 | 25 |

| 26 | 27 | 28 | 29 | 30 | 31 | |

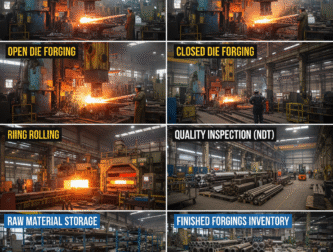

Scope of Forging Consultancy Services We offer comprehensive forging c

Screw Press for Titanium and Aluminum Screw Press for Titanium and Alu

Set up your complete forging line with expert consultant Amit Singh. F

India Best Young Forging Consultant Amit Singh

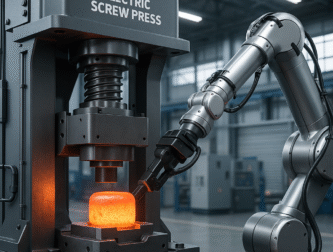

Electric Screw Press: Types, Benefits, Advantages, and Services Electr

Adhvika Forge Tech offers advanced Electric Screw Presses (250–8500

🇮🇳 Aluminum Alloy Forging आज भी भारत में �

Expert Forging Consultant Amit Singh specializes in Die Design, Forgin

Blog: The Art and Science of Forging: A Key Player in Manufacturing Ex

we specialize in providing end-to-end services for the installation an

Why Electric Screw Press Offers the Cheapest Forging Cost Introduction

We handle complete services for all types of forging presses, includin

Adhvika Forge Tech manufactures Direct Drive (DD) Forging Presses powe

Adhvika Forge Tech’s Bangalore factory delivers world-class forging

Join us at IMTEX FORMING 2026 and explore how Forging Consultant can h

Claw Pole Forging Solution – Complete Turnkey Process for Automob

Get expert Forging Consultancy Services from Forging Consultant – tu

High-performance materials like titanium, alloys & composites drive ae

Aluminum forging is a manufacturing process in which aluminum alloy is

Turnkey Solutions from design to production we gives you best Turnkey

Top 10 Electric Screw Press Brand & Manufacturers Top 10 Electric Scre

Automotive Drivetrains to Connect the Driveshaft to the Transmission o

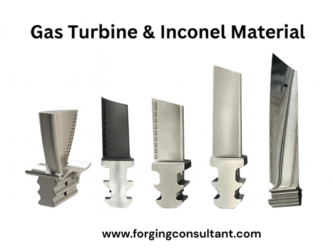

Inconel,Nimonic,Hastelloy,Nickel, Stellite Forging Solution

The cost of a 1000 Ton Electric Screw Press depends on whether you’r

Complete Hip Stem Forging Line Setup by Forging Consultant Precision F

Amit Singh is a leading forging consultant offering expertise in plant

Forging Consultant provides the best turnkey solutions for bombshell p

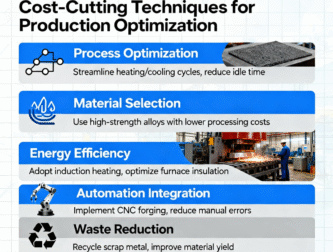

Cost-Cutting Techniques in Forging: Optimize Production Without Compro

Automation in forging with robots cuts cycle time by 40%, boosts outpu

Explore how 10 per kg forging rates are becoming the benchmark for ind

Open Die Forging Plant Setup – Inconel | Duplex | Super Duplex | Ste

How We Work – End-to-End Forging Solutions At Adhvika Forge Tech, le

630 Ton Electric Screw Press Price 630-ton Electric Screw Press avai

Why Choose a Forging Consultant? Are you planning to start or upgrade

Comparing Chinese and Indian screw presses in the forging industry inv

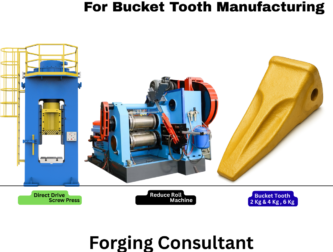

Compare forged vs cast bucket teeth: durability, wear resistance, cost

Aluminum Crown Forging Experts – Precision, Efficiency & Durabil

Complete Turnkey Solution for Bucket Tooth Manufacturing

Adhvika Forge Tech provides skilled forging manpower supply, covering

1️⃣ Material Selection Matters 🏗️ – Choosing the right allo

Aluminum and aluminum alloy forging involves shaping these materials t

Direct Drive Electric Screw Press – Energy saving, high precision &

At Forging Consultant, we provide turnkey solutions for closed die for

High-Strength Railway Forging Components – End-to-End Solutions for

Why Forging Consultant Services Are Essential for Your Business Runnin

The forging industry is evolving rapidly, with advancements in technol

In the dynamic and demanding world of forging, where precision, effici

Amit Singh – A Global Forging Consultant Changing the Future of Forg

India Best Supplier Hot Forging Press Top 10 AD Electric Screw Press &

Discover Amit Singh’s expertise in forging consultancy and turnk

The railway forging industry is evolving fast 🚆 — blending human

Forging Consultancy Group is proud to participate in Metal Forming Exp

A Ring Rolling Machine is used to manufacture hollow, ring-shaped comp

Shaping the Future of Forging with Vision, Experience & Innovation

Error: Contact form not found.