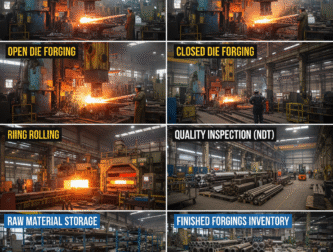

At Adhvika Forge Tech, led by Forging Consultant Amit Singh, we provide complete forging solutions to industries worldwide. Our expertise spans from conceptualizing a forging project to executing it efficiently with precision, cost-effectiveness, and high-quality standards. Our work process ensures every step is handled professionally, so clients can rely on us as a single-window solution provider for open die forging, closed die forging, cold forging, and precision alloy components.

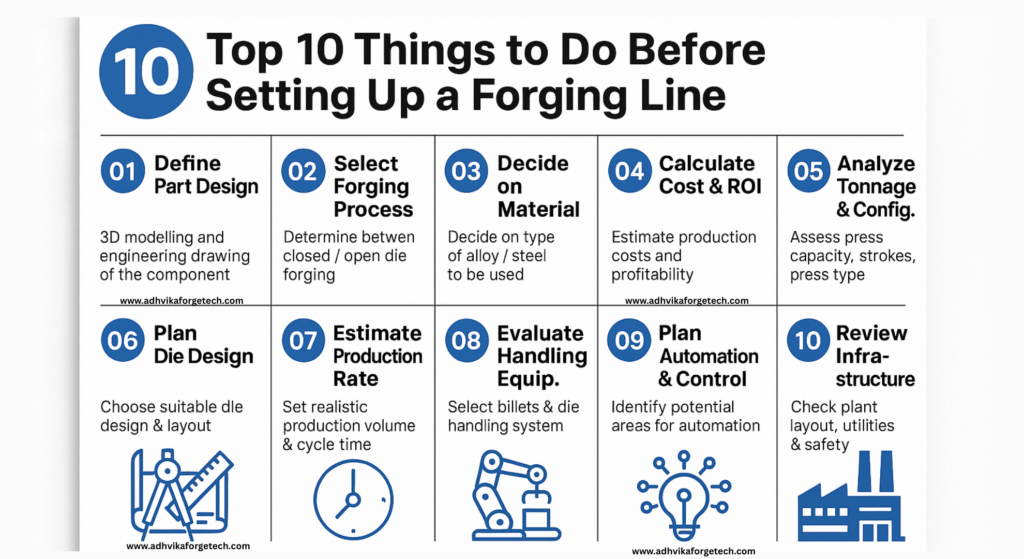

We begin every project with a detailed evaluation of client requirements, production targets, and material specifications. Our forging plant setup services include:

Site Selection & Layout Planning: Determining the optimal plant layout to ensure smooth material flow, safe working zones, efficient energy usage, and future expansion potential.

Civil & Structural Work Planning: Guidance on foundations, flooring, crane paths, and structural support tailored to forging machines, presses, and hammers.

Utility Planning: Assessment and provision of electrical load, compressed air, water cooling, and other utilities essential for high-capacity forging operations.

Our goal is to ensure the plant setup is efficient, safe, and scalable, allowing clients to achieve maximum productivity with minimal downtime.

Choosing the right machine is crucial to ensure precise forging, material saving, and cost efficiency. We help clients select machinery based on:

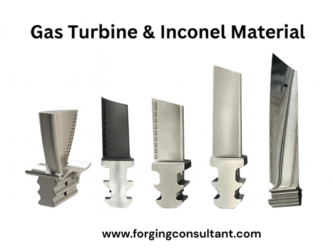

Material Types: Steel, aluminum alloys, titanium, Inconel, super duplex, and other exotic alloys.

Component Complexity: Simple shafts or high-precision aerospace and automotive parts.

Production Volume: From small-batch prototyping to high-volume mass production.

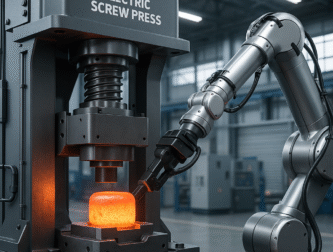

Press Types & Capacity: Electric screw presses, direct drive screw presses, mechanical presses, double-column hammers, pneumatic hammers, upsetting machines, trimming presses, and ring rolling machines.

We also negotiate with global and local manufacturers, ensuring clients get the best combination of quality, technology, and cost.

Effective project execution is key to achieving deadlines and budgets. Our project management approach covers:

Planning & Scheduling: Detailed timelines for plant setup, machine installation, and trial production.

Coordination: Seamless communication between civil contractors, machine suppliers, tool designers, and manpower teams.

Monitoring & Quality Control: Regular inspection of machine installation, foundation alignment, hydraulic & electrical connections, and trial runs.

Automation & Industry 4.0 Integration: Implementing automated material handling, robotic forging, and digital monitoring for precision and efficiency.

Our experienced team ensures projects are delivered on time, within budget, and without compromising on quality.

We specialize in forging component design and tooling development:

Die Design & Simulation: Using advanced CAD/CAM and forging simulation software to optimize die geometry, minimize material wastage, and improve component quality.

Bolster & Fixture Design: Ensuring long die life, safe operations, and uniform load distribution.

Prototype Development: Rapid development of sample components for trials and process validation.

Material Selection & Heat Treatment: Advising on suitable alloys and processing techniques for durability, strength, and corrosion resistance.

Our focus is on delivering components with high dimensional accuracy, minimal defects, and optimal material utilization.

Accurate costing is critical to profitability in forging projects. We provide:

Raw Material Estimation: Based on current market rates, scrap allowance, and material yield calculations.

Process Costing: Considering forging, trimming, heat treatment, machining, inspection, and logistics.

Manpower & Overhead Analysis: Detailed cost for operators, engineers, and support staff.

ROI & Break-Even Analysis: Helping clients forecast profitability and set realistic pricing strategies.

By providing a transparent and detailed costing analysis, we help clients make informed decisions and maximize ROI.

We provide skilled manpower for every stage of forging operations:

Machine Operators: Trained in running screw presses, hammers, hydraulic presses, and ring rolling machines.

Tooling & Die Experts: For die installation, maintenance, and adjustment.

Engineers & Supervisors: Managing production, quality, and process optimization.

Support Staff: Safety officers, logistics coordinators, and material handlers.

Our manpower solutions are flexible, skilled, and trained according to industry standards, ensuring smooth operations from day one.

By integrating all these services, Adhvika Forge Tech offers a true turnkey solution:

Plant design and civil foundation

Machine selection, procurement, and installation

Process design and component development

Costing, ROI analysis, and manpower supply

Trial production, quality assurance, and automation

Our commitment to excellence, innovation, and client satisfaction makes us a trusted partner in the forging industry. Whether it is automotive shafts, aerospace components, defense parts, medical implants, or industrial forgings, we ensure clients receive complete, efficient, and cost-effective solutions under one roof.

| M | T | W | T | F | S | S |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |||

| 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| 19 | 20 | 21 | 22 | 23 | 24 | 25 |

| 26 | 27 | 28 | 29 | 30 | 31 | |

Scope of Forging Consultancy Services We offer comprehensive forging c

Screw Press for Titanium and Aluminum Screw Press for Titanium and Alu

Set up your complete forging line with expert consultant Amit Singh. F

India Best Young Forging Consultant Amit Singh

Electric Screw Press: Types, Benefits, Advantages, and Services Electr

Adhvika Forge Tech offers advanced Electric Screw Presses (250–8500

🇮🇳 Aluminum Alloy Forging आज भी भारत में �

Expert Forging Consultant Amit Singh specializes in Die Design, Forgin

Blog: The Art and Science of Forging: A Key Player in Manufacturing Ex

we specialize in providing end-to-end services for the installation an

Why Electric Screw Press Offers the Cheapest Forging Cost Introduction

We handle complete services for all types of forging presses, includin

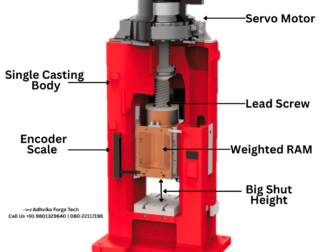

Adhvika Forge Tech manufactures Direct Drive (DD) Forging Presses powe

Adhvika Forge Tech’s Bangalore factory delivers world-class forging

Join us at IMTEX FORMING 2026 and explore how Forging Consultant can h

Claw Pole Forging Solution – Complete Turnkey Process for Automob

Get expert Forging Consultancy Services from Forging Consultant – tu

High-performance materials like titanium, alloys & composites drive ae

Aluminum forging is a manufacturing process in which aluminum alloy is

Turnkey Solutions from design to production we gives you best Turnkey

Top 10 Electric Screw Press Brand & Manufacturers Top 10 Electric Scre

Automotive Drivetrains to Connect the Driveshaft to the Transmission o

Inconel,Nimonic,Hastelloy,Nickel, Stellite Forging Solution

The cost of a 1000 Ton Electric Screw Press depends on whether you’r

Complete Hip Stem Forging Line Setup by Forging Consultant Precision F

Amit Singh is a leading forging consultant offering expertise in plant

Forging Consultant provides the best turnkey solutions for bombshell p

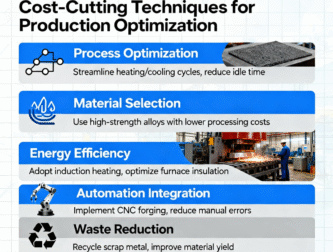

Cost-Cutting Techniques in Forging: Optimize Production Without Compro

Automation in forging with robots cuts cycle time by 40%, boosts outpu

Explore how 10 per kg forging rates are becoming the benchmark for ind

Open Die Forging Plant Setup – Inconel | Duplex | Super Duplex | Ste

How We Work – End-to-End Forging Solutions At Adhvika Forge Tech, le

630 Ton Electric Screw Press Price 630-ton Electric Screw Press avai

Why Choose a Forging Consultant? Are you planning to start or upgrade

Comparing Chinese and Indian screw presses in the forging industry inv

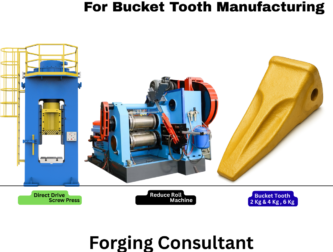

Compare forged vs cast bucket teeth: durability, wear resistance, cost

Aluminum Crown Forging Experts – Precision, Efficiency & Durabil

Complete Turnkey Solution for Bucket Tooth Manufacturing

Adhvika Forge Tech provides skilled forging manpower supply, covering

1️⃣ Material Selection Matters 🏗️ – Choosing the right allo

Aluminum and aluminum alloy forging involves shaping these materials t

Direct Drive Electric Screw Press – Energy saving, high precision &

At Forging Consultant, we provide turnkey solutions for closed die for

High-Strength Railway Forging Components – End-to-End Solutions for

Why Forging Consultant Services Are Essential for Your Business Runnin

The forging industry is evolving rapidly, with advancements in technol

In the dynamic and demanding world of forging, where precision, effici

Amit Singh – A Global Forging Consultant Changing the Future of Forg

India Best Supplier Hot Forging Press Top 10 AD Electric Screw Press &

Discover Amit Singh’s expertise in forging consultancy and turnk

The railway forging industry is evolving fast 🚆 — blending human

Forging Consultancy Group is proud to participate in Metal Forming Exp

A Ring Rolling Machine is used to manufacture hollow, ring-shaped comp

Shaping the Future of Forging with Vision, Experience & Innovation

Error: Contact form not found.