Amit Singh has emerged as one of India’s most dynamic and visionary young forging consultants. Recognized for his deep knowledge, innovative approach, and hands-on experience in both closed die and open die forging, Amit has made remarkable strides in modernizing the forging industry. At a time when many professionals are confined to office-based roles, Amit has consistently stayed close to the shopfloor, understanding the intricate challenges and technical nuances of forging operations.

Amit Singh is fundamentally an Electrical Engineer, a foundation that provided him with a solid understanding of industrial automation, drives, and modern machinery operations. However, Amit’s real education began on the forging shopfloors. During his career, he worked with some of India’s leading forging companies, including Bharat Forge, Ramkrishna Forging, Mahindra CIA, and many more. These opportunities exposed him to a diverse range of forging operations—from automobile components to heavy industrial machinery parts—allowing him to gain hands-on experience with various forging presses, hammers, manipulators, and automation systems.

During his tenure, Amit witnessed firsthand the gaps and inefficiencies in forging operations. He observed how manpower shortages, improper die design, inefficient forging presses, and lack of process standardization led to high component rejection rates, material wastage, and reduced production efficiency. These experiences became the foundation of his vision: to transform the forging industry in India and globally by implementing smart, automated, and cost-effective forging solutions.

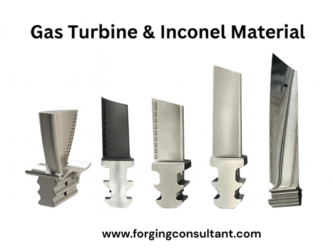

Amit Singh’s understanding of the forging industry goes beyond simple operations. He has studied both Indian and global markets, noting the growing demand for high-precision, lightweight, and high-strength components in sectors such as automotive, aerospace, defense, oil & gas, and medical. He recognized that while global companies were moving toward automated and digitally integrated forging lines, many Indian industries were still dependent on traditional processes, often resulting in low efficiency and high scrap rates.

With this insight, Amit has focused on bridging the technology gap. His expertise allows him to analyze client requirements and recommend solutions that combine modern machinery, optimized die designs, automation systems, and proper manpower training. By doing so, he ensures that forging companies not only improve product quality but also reduce production costs and increase overall efficiency.

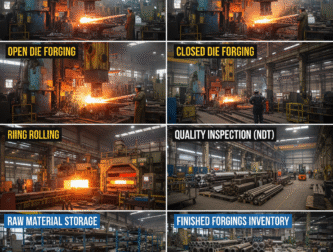

Amit Singh’s specialization spans both closed die and open die forging—the two pillars of the forging industry.

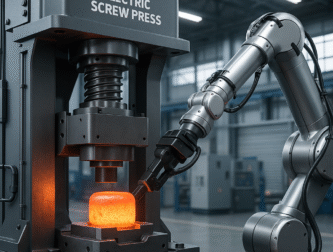

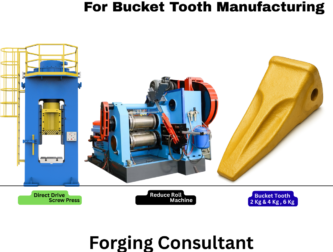

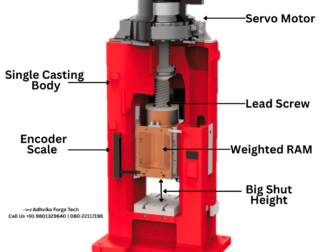

Closed Die Forging: Amit has extensive experience in high-precision automotive, aerospace, and industrial components. He works on projects involving shafts, flanges, control arms, gears, and complex-shaped parts, ensuring tight tolerances, optimized material usage, and minimum rejection. He is well-versed in Electric Screw Presses, Direct Drive Screw Presses, CNC Hammers, and Hydraulic Presses, integrating automation and Industry 4.0 principles wherever possible.

Open Die Forging: Amit’s work in open die forging includes large shafts, axles, turbine components, and industrial equipment parts. He has designed and implemented turnkey open die forging solutions, including manipulator systems, hot forging layouts, heating furnaces, and material handling processes. His approach emphasizes reducing die and material stress, improving grain flow, and extending equipment life.

Amit Singh’s career experiences have shaped a clear vision for the forging industry. He aims to modernize Indian forging plants and guide them toward smart, automated, and integrated lines. His approach includes:

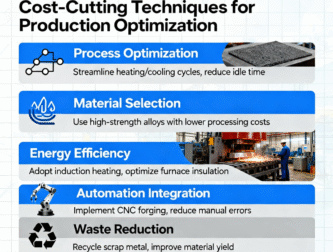

Advanced Technology Integration: Implementing electric screw presses, direct drive presses, CNC hammers, robotic manipulators, and automated trimming presses to improve speed and precision.

Optimized Die and Bolster Design: Amit emphasizes stress-free forging dies, better material flow, and longer die life, which reduces maintenance costs and scrap rates.

Automation and Industry 4.0: Introducing AI-based monitoring, predictive maintenance, and digital process control to enhance productivity and reduce human error.

Manpower Training: Amit recognizes that even the most advanced machinery requires skilled operators. He provides hands-on training for shopfloor engineers and operators, ensuring optimal machine use, safety, and consistency in quality.

Process Standardization: Establishing repeatable, high-quality forging processes to meet both domestic and international standards, improving global competitiveness.

Amit Singh has already contributed to multiple successful projects across India, improving operations in both small-scale and large forging industries. His key achievements include:

Designing and implementing high-precision closed die forging lines for automotive components, reducing material scrap by 20–30%.

Developing open die forging lines with manipulators for heavy industrial components, improving efficiency and reducing labor dependency.

Introducing direct drive and electric screw presses in plants where traditional mechanical presses were limiting production capacity.

Providing end-to-end consultancy including die design, process development, manpower training, and quality control, ensuring turnkey solutions for clients.

Through these efforts, Amit has proven that smart forging solutions are not only technically feasible but also economically viable.

Amit Singh has a unique ability to identify the root causes of operational challenges:

High Rejection Rates: Often caused by improper die design, poor material handling, or underpowered forging presses.

Manpower Inefficiency: Lack of skilled operators leads to inconsistent quality and slower production.

Aging Machinery: Many Indian plants use old mechanical presses that are energy-intensive and maintenance-heavy.

Process Bottlenecks: Poorly planned workflows and heat treatment cycles slow production.

By addressing these issues with modern equipment, process redesign, and automation, Amit helps plants maximize output while minimizing cost and effort.

While Amit’s work is rooted in Indian industry, his vision is global. He studies international forging trends, including aerospace precision forging, automotive lightweighting, and high-tech defense components. His solutions combine global best practices with Indian cost-effectiveness, allowing Indian forging companies to compete with international manufacturers.

Amit Singh represents the next generation of forging consultants in India. With a combination of technical expertise, hands-on shopfloor experience, and visionary thinking, he is reshaping the forging industry by promoting:

Smart, automated forging lines

Efficient and precise closed die and open die processes

Cost-effective solutions without compromising quality

Advanced die design and material optimization

Skilled manpower and process standardization

His work ensures that Indian forging companies move toward a smarter, faster, and more competitive future, setting new benchmarks for quality, efficiency, and innovation.

Partnering with Amit Singh means you gain more than a consultant—you gain a strategic partner who understands every detail of forging, from shopfloor realities to global market demands. His mission is clear: Increase industrial efficiency, reduce wastage, and bring Indian forging to the forefront of modern technology.

#AmitSingh #ForgingConsultant #OpenDieForging #ClosedDieForging #ElectricScrewPress #DirectDrivePress #ForgingAutomation #SmartForging #ForgingIndia #IndustrialConsultancy

| M | T | W | T | F | S | S |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |||

| 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| 19 | 20 | 21 | 22 | 23 | 24 | 25 |

| 26 | 27 | 28 | 29 | 30 | 31 | |

Scope of Forging Consultancy Services We offer comprehensive forging c

Screw Press for Titanium and Aluminum Screw Press for Titanium and Alu

Set up your complete forging line with expert consultant Amit Singh. F

India Best Young Forging Consultant Amit Singh

Electric Screw Press: Types, Benefits, Advantages, and Services Electr

Adhvika Forge Tech offers advanced Electric Screw Presses (250–8500

🇮🇳 Aluminum Alloy Forging आज भी भारत में �

Expert Forging Consultant Amit Singh specializes in Die Design, Forgin

Blog: The Art and Science of Forging: A Key Player in Manufacturing Ex

we specialize in providing end-to-end services for the installation an

Why Electric Screw Press Offers the Cheapest Forging Cost Introduction

We handle complete services for all types of forging presses, includin

Adhvika Forge Tech manufactures Direct Drive (DD) Forging Presses powe

Adhvika Forge Tech’s Bangalore factory delivers world-class forging

Join us at IMTEX FORMING 2026 and explore how Forging Consultant can h

Claw Pole Forging Solution – Complete Turnkey Process for Automob

Get expert Forging Consultancy Services from Forging Consultant – tu

High-performance materials like titanium, alloys & composites drive ae

Aluminum forging is a manufacturing process in which aluminum alloy is

Turnkey Solutions from design to production we gives you best Turnkey

Top 10 Electric Screw Press Brand & Manufacturers Top 10 Electric Scre

Automotive Drivetrains to Connect the Driveshaft to the Transmission o

Inconel,Nimonic,Hastelloy,Nickel, Stellite Forging Solution

The cost of a 1000 Ton Electric Screw Press depends on whether you’r

Complete Hip Stem Forging Line Setup by Forging Consultant Precision F

Amit Singh is a leading forging consultant offering expertise in plant

Forging Consultant provides the best turnkey solutions for bombshell p

Cost-Cutting Techniques in Forging: Optimize Production Without Compro

Automation in forging with robots cuts cycle time by 40%, boosts outpu

Explore how 10 per kg forging rates are becoming the benchmark for ind

Open Die Forging Plant Setup – Inconel | Duplex | Super Duplex | Ste

How We Work – End-to-End Forging Solutions At Adhvika Forge Tech, le

630 Ton Electric Screw Press Price 630-ton Electric Screw Press avai

Why Choose a Forging Consultant? Are you planning to start or upgrade

Comparing Chinese and Indian screw presses in the forging industry inv

Compare forged vs cast bucket teeth: durability, wear resistance, cost

Aluminum Crown Forging Experts – Precision, Efficiency & Durabil

Complete Turnkey Solution for Bucket Tooth Manufacturing

Adhvika Forge Tech provides skilled forging manpower supply, covering

1️⃣ Material Selection Matters 🏗️ – Choosing the right allo

Aluminum and aluminum alloy forging involves shaping these materials t

Direct Drive Electric Screw Press – Energy saving, high precision &

At Forging Consultant, we provide turnkey solutions for closed die for

High-Strength Railway Forging Components – End-to-End Solutions for

Why Forging Consultant Services Are Essential for Your Business Runnin

The forging industry is evolving rapidly, with advancements in technol

In the dynamic and demanding world of forging, where precision, effici

Amit Singh – A Global Forging Consultant Changing the Future of Forg

India Best Supplier Hot Forging Press Top 10 AD Electric Screw Press &

Discover Amit Singh’s expertise in forging consultancy and turnk

The railway forging industry is evolving fast 🚆 — blending human

Forging Consultancy Group is proud to participate in Metal Forming Exp

A Ring Rolling Machine is used to manufacture hollow, ring-shaped comp

Shaping the Future of Forging with Vision, Experience & Innovation

Error: Contact form not found.